Understanding Manufacturing Industries: A Complete Flowchart and Evaluation for Class 10

Associated Articles: Understanding Manufacturing Industries: A Complete Flowchart and Evaluation for Class 10

Introduction

With enthusiasm, let’s navigate via the intriguing matter associated to Understanding Manufacturing Industries: A Complete Flowchart and Evaluation for Class 10. Let’s weave attention-grabbing info and provide contemporary views to the readers.

Desk of Content material

Understanding Manufacturing Industries: A Complete Flowchart and Evaluation for Class 10

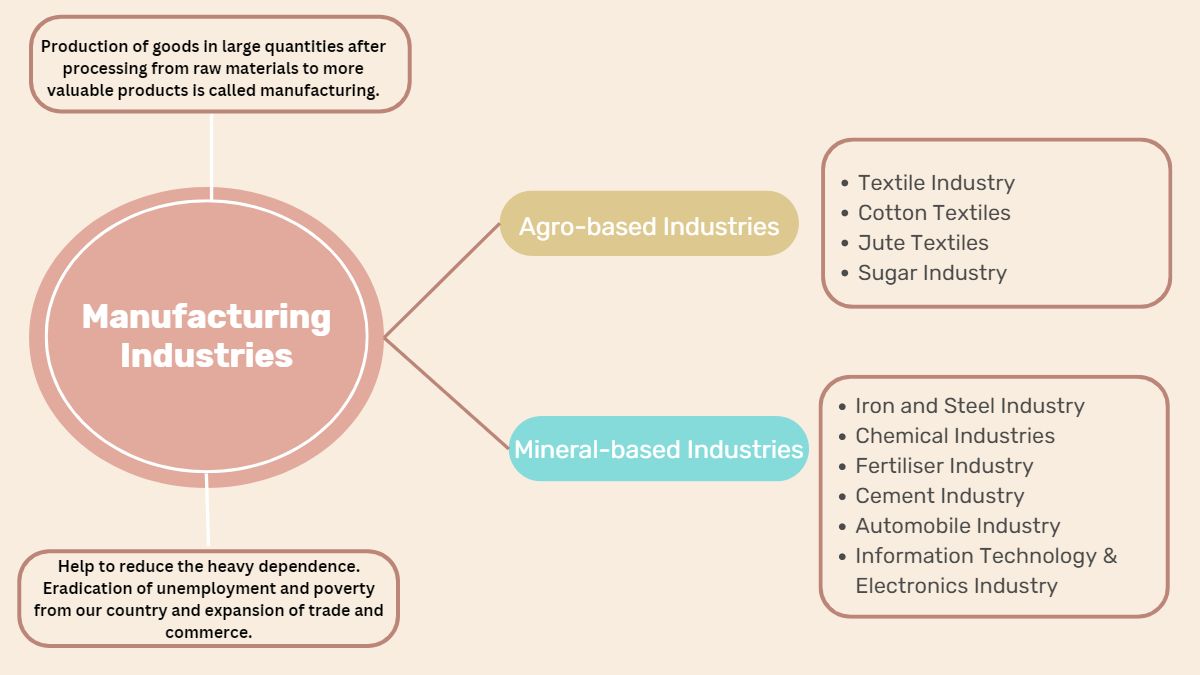

Manufacturing industries kind the spine of many economies, remodeling uncooked supplies into completed items that we use each day. Understanding their processes is essential for comprehending international commerce, financial progress, and technological developments. This text explores the intricacies of producing industries, presenting an in depth flowchart outlining the important thing levels concerned, after which delving deeper into every stage with examples and explanations appropriate for a Class 10 understanding.

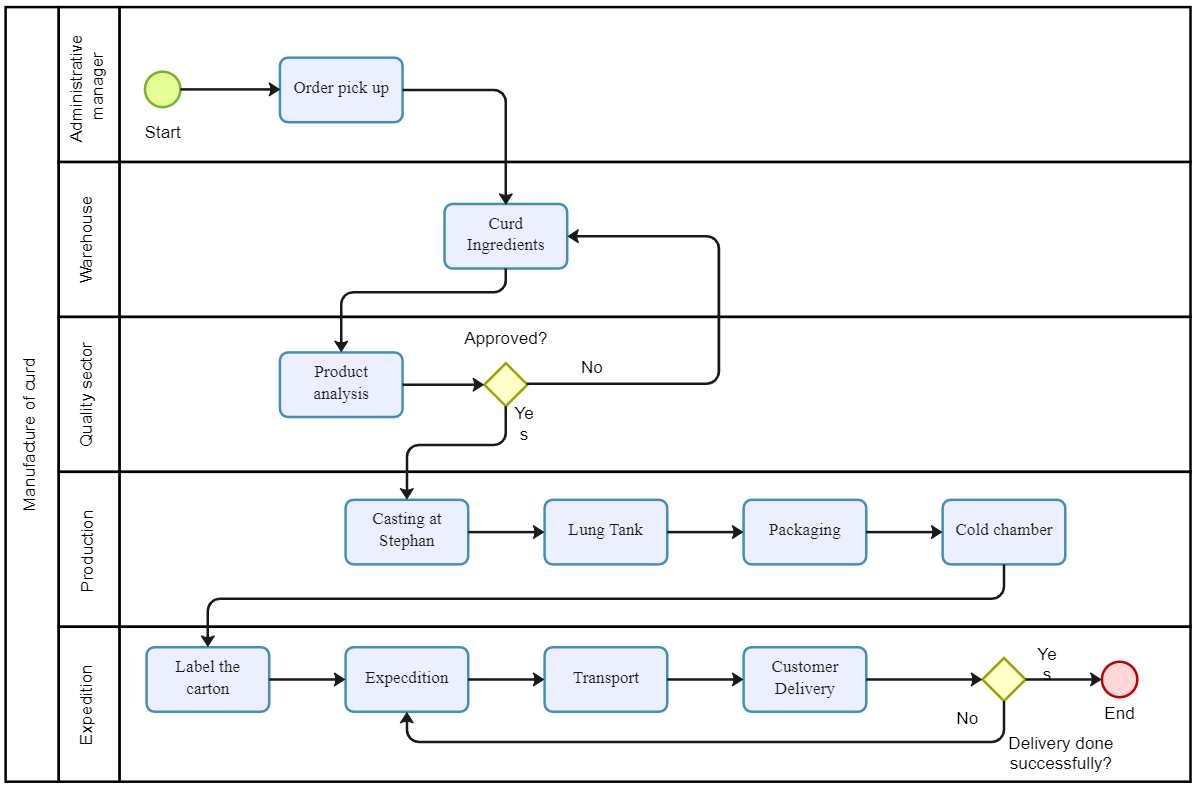

I. The Manufacturing Course of Flowchart:

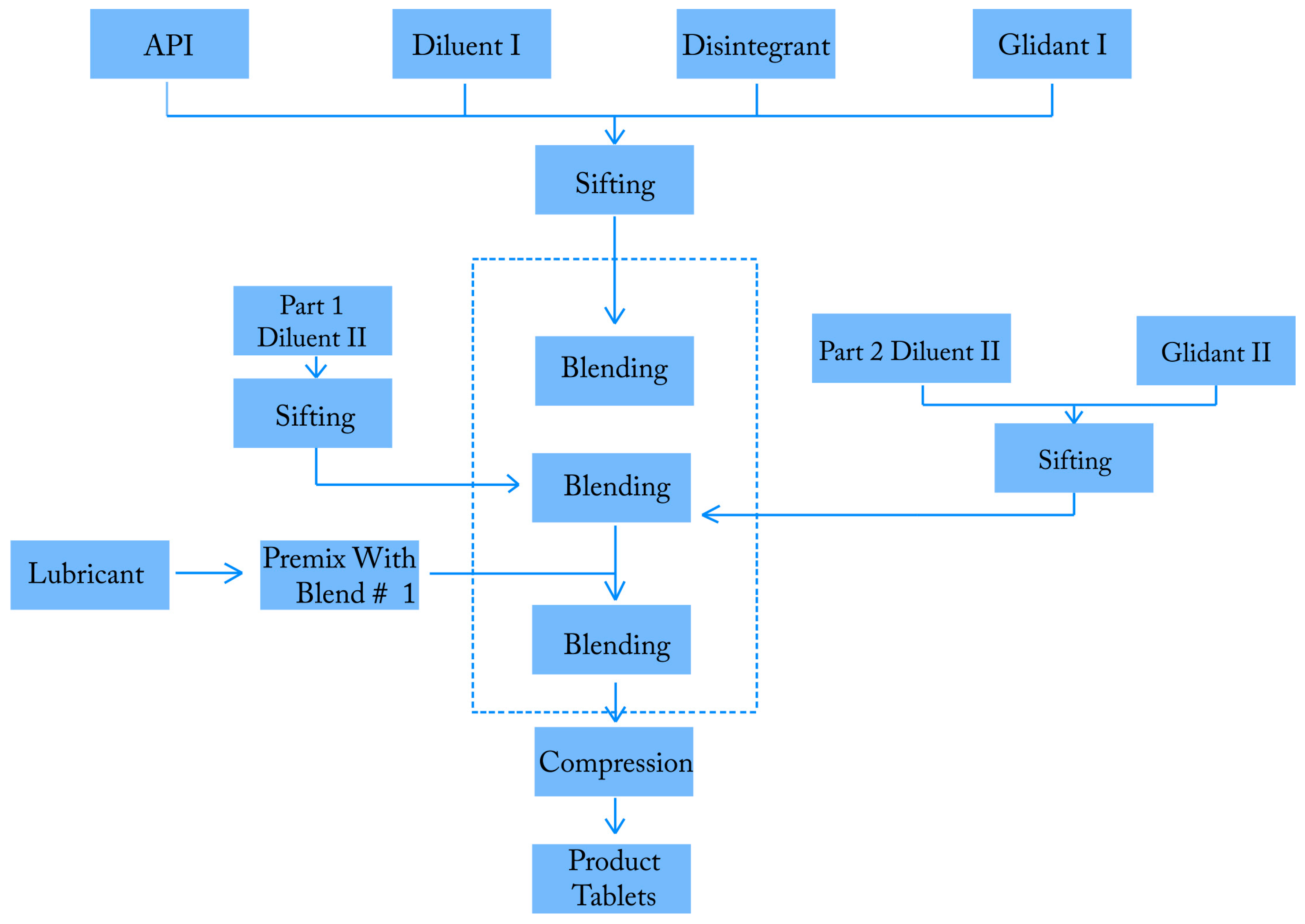

The next flowchart depicts a generalized manufacturing course of. Particular steps and their order would possibly differ relying on the business and product.

graph TD

A[Raw Material Acquisition] --> BRaw Materials Processing;

B --> C[Design & Engineering];

C --> D[Production Planning];

D --> E[Manufacturing];

E --> F[Quality Control];

F --> G[Packaging & Distribution];

G --> H[Sales & Marketing];

H --> I[Customer Feedback];

I --> A;

fashion A fill:#f9f,stroke:#333,stroke-width:2px

fashion I fill:#ccf,stroke:#333,stroke-width:2pxII. Detailed Clarification of Every Stage:

A. Uncooked Materials Acquisition: That is the foundational stage. It entails sourcing the mandatory uncooked supplies required for manufacturing. This might contain:

- Extraction: Mining for ores, drilling for oil, logging for timber.

- Agriculture: Harvesting crops like cotton, wheat, or sugarcane.

- Buying: Shopping for pre-processed supplies from suppliers, akin to metal, plastics, or digital parts.

Examples:

- A textile mill buying cotton from farmers.

- An car producer buying metal from a metal plant.

- A meals processing firm shopping for vegatables and fruits from farms.

Elements influencing this stage:

- Value: The worth of uncooked supplies considerably impacts the ultimate product’s price.

- Availability: Guaranteeing a constant provide of uncooked supplies is essential for uninterrupted manufacturing.

- High quality: The standard of uncooked supplies instantly impacts the standard of the completed product. Strict high quality checks are sometimes carried out at this stage.

- Sustainability: More and more, producers are specializing in sourcing sustainable and ethically produced uncooked supplies.

B. Uncooked Materials Processing: This stage entails remodeling uncooked supplies right into a kind appropriate for manufacturing. This will likely embody:

- Cleansing: Eradicating impurities or undesirable parts.

- Chopping: Shaping uncooked supplies into usable sizes.

- Refining: Purifying supplies to boost their properties (e.g., refining crude oil into petrol).

- Mixing: Combining totally different supplies to create a composite materials.

Examples:

- Cleansing and ginning cotton earlier than spinning.

- Refining crude oil into numerous petroleum merchandise.

- Mixing elements for baking a cake in a meals processing manufacturing facility.

C. Design & Engineering: This important stage entails the creation of detailed plans and specs for the product. It encompasses:

- Product Design: Creating the product’s look, performance, and person expertise.

- Course of Design: Figuring out the manufacturing strategies and methods to be employed.

- Testing & Prototyping: Creating prototypes to check the design and determine potential flaws.

Examples:

- Designing a brand new smartphone mannequin, together with its options and inner parts.

- Engineering the manufacturing course of for a brand new automotive, together with the meeting line structure.

- Designing the packaging for a brand new meals product.

D. Manufacturing Planning: This stage entails organizing and scheduling the manufacturing course of. It contains:

- Capability Planning: Figuring out the manufacturing capability required to satisfy demand.

- Scheduling: Making a manufacturing schedule that outlines the sequence of operations.

- Stock Administration: Managing the inventory of uncooked supplies, work-in-progress, and completed items.

Examples:

- Figuring out the variety of automobiles to be produced per day on an meeting line.

- Scheduling the manufacturing of various kinds of clothes gadgets in a garment manufacturing facility.

- Managing the stock of uncooked supplies in a meals processing plant.

E. Manufacturing: That is the core stage the place the precise manufacturing takes place. It will probably contain numerous processes, together with:

- Mass Manufacturing: Producing massive portions of equivalent merchandise utilizing automated equipment (e.g., automotive manufacturing).

- Customized Manufacturing: Producing distinctive or custom-made merchandise to satisfy particular buyer necessities (e.g., bespoke tailoring).

- Additive Manufacturing (3D Printing): Creating merchandise layer by layer from a digital design.

Examples:

- Meeting of digital parts on a circuit board.

- Weaving cloth on a loom.

- Casting steel components in a foundry.

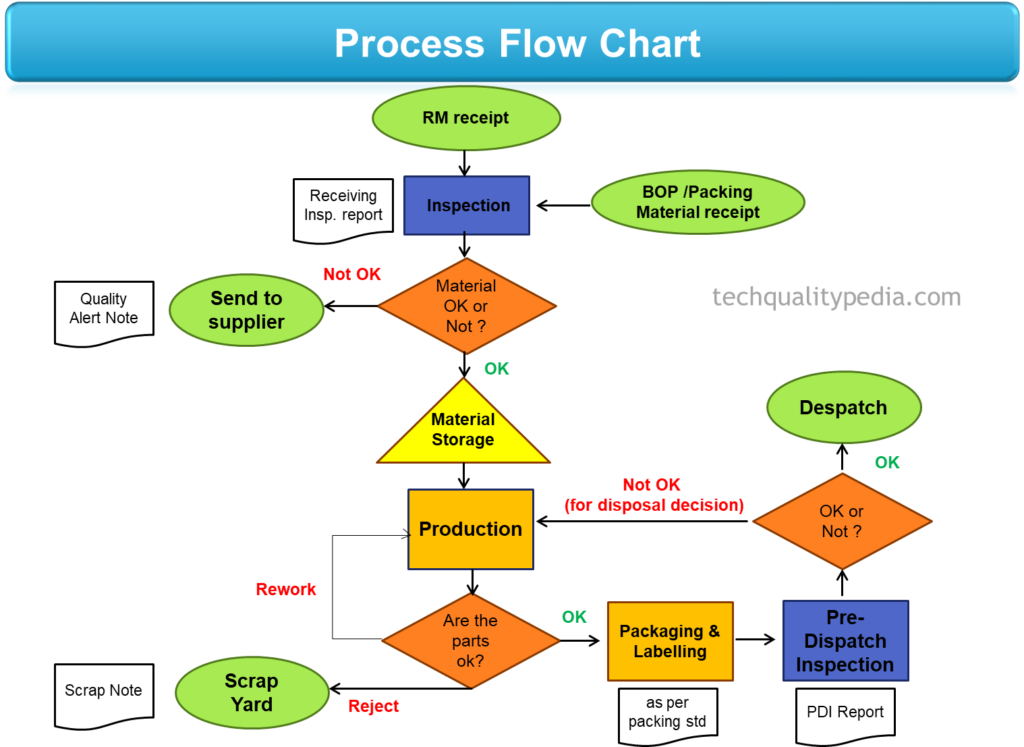

F. High quality Management: This stage ensures that the manufactured merchandise meet the required high quality requirements. It entails:

- Inspection: Checking merchandise for defects at numerous levels of manufacturing.

- Testing: Conducting exams to make sure merchandise meet specs.

- Corrective Actions: Taking steps to rectify any recognized defects or high quality points.

Examples:

- Inspecting automotive components for defects earlier than meeting.

- Testing digital units for performance.

- Implementing high quality management measures in meals processing to stop contamination.

G. Packaging & Distribution: This stage entails getting ready the completed merchandise for transportation and sale. It contains:

- Packaging: Defending the product throughout transportation and enhancing its presentation.

- Warehousing: Storing completed items earlier than distribution.

- Transportation: Transferring completed items to distribution facilities or on to clients.

Examples:

- Packaging meals merchandise in hermetic containers.

- Warehousing clothes gadgets earlier than delivery to retailers.

- Transporting vehicles from the manufacturing facility to dealerships.

H. Gross sales & Advertising and marketing: This stage focuses on promoting the completed merchandise to clients. It entails:

- Advertising and marketing: Selling the product to potential clients via numerous channels.

- Gross sales: Promoting the product to clients.

- Buyer Service: Offering assist to clients after the sale.

Examples:

- Promoting a brand new automotive mannequin on tv.

- Promoting clothes gadgets in a retail retailer.

- Offering technical assist for digital units.

I. Buyer Suggestions: This important stage entails gathering suggestions from clients to enhance future merchandise and processes. This suggestions could be collected via:

- Surveys: Accumulating buyer opinions via questionnaires.

- Critiques: Monitoring on-line critiques and suggestions.

- Buyer Service Interactions: Gathering suggestions throughout customer support calls or interactions.

Examples:

- Analyzing buyer critiques of a smartphone on on-line platforms.

- Conducting surveys to evaluate buyer satisfaction with a meals product.

- Utilizing buyer suggestions to enhance the design of a brand new automotive mannequin.

III. Conclusion:

Manufacturing industries are complicated techniques involving quite a few levels and processes. Understanding these levels, as outlined within the flowchart and detailed rationalization, is essential for appreciating the vastness and significance of this sector in our international financial system. From uncooked materials acquisition to buyer suggestions, every stage performs an important function in delivering high quality merchandise to shoppers. Moreover, understanding these processes may help college students admire the interconnectedness of various industries and the affect of technological developments on manufacturing practices. This information supplies a strong basis for additional exploration of specialised manufacturing processes and their contribution to society.

Closure

Thus, we hope this text has offered helpful insights into Understanding Manufacturing Industries: A Complete Flowchart and Evaluation for Class 10. We admire your consideration to our article. See you in our subsequent article!