R-Chart Instance Issues with Options: Mastering Course of Variability Management

Associated Articles: R-Chart Instance Issues with Options: Mastering Course of Variability Management

Introduction

On this auspicious event, we’re delighted to delve into the intriguing matter associated to R-Chart Instance Issues with Options: Mastering Course of Variability Management. Let’s weave fascinating data and provide contemporary views to the readers.

Desk of Content material

R-Chart Instance Issues with Options: Mastering Course of Variability Management

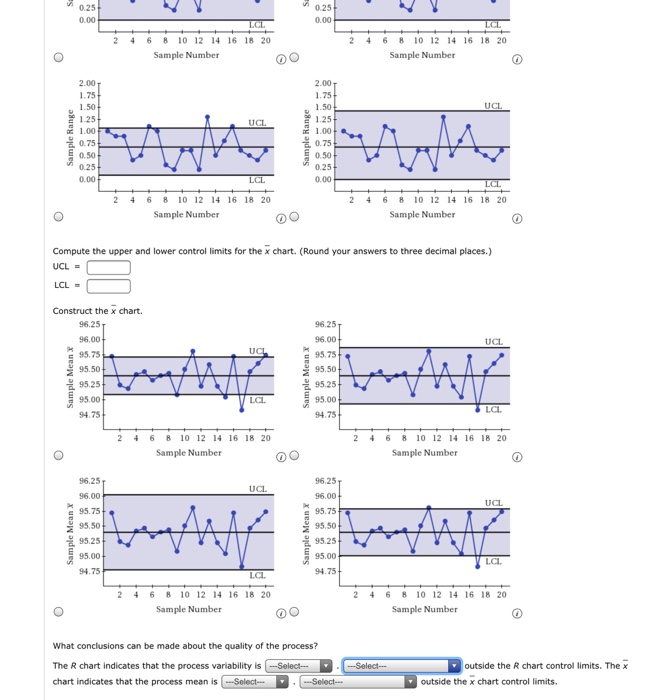

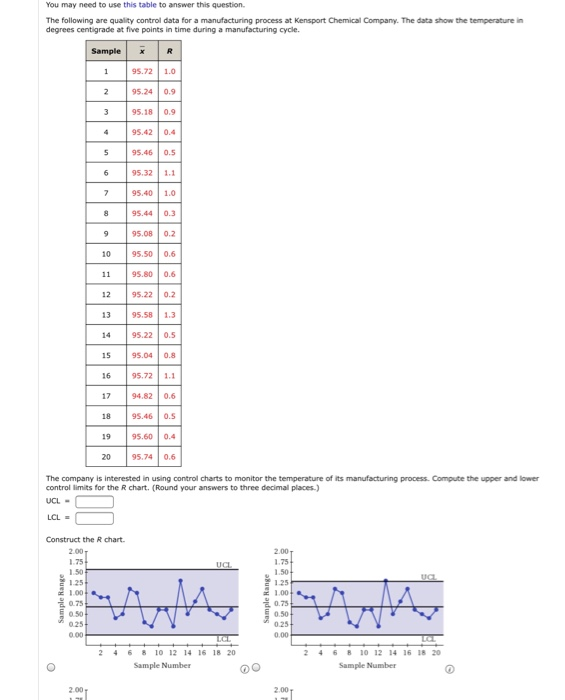

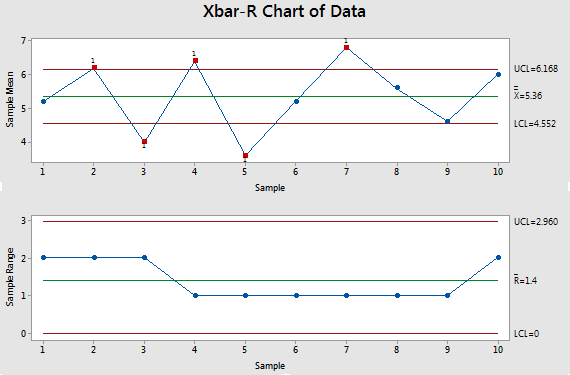

The R-chart, an important software in Statistical Course of Management (SPC), is used to watch the variability inside subgroups of information. In contrast to the X-bar chart which tracks the common, the R-chart focuses solely on the vary – the distinction between the best and lowest values inside every subgroup. Understanding and deciphering R-charts is significant for figuring out shifts in course of variability, stopping defects, and bettering total course of functionality. This text presents a number of instance issues with detailed options, illustrating the applying of R-charts and emphasizing the interpretation of their outcomes.

Understanding the Fundamentals:

Earlier than diving into the examples, let’s briefly recap the important thing ideas:

- Subgroups: Information is collected in subgroups (e.g., samples taken hourly, day by day batches). The dimensions of those subgroups (n) is essential and may stay constant all through the method.

- Vary (R): The distinction between the biggest and smallest statement inside every subgroup.

- Common Vary (R-bar): The common of the ranges calculated for all subgroups.

-

Management Limits: These are calculated utilizing management chart constants (d2, D3, D4) particular to the subgroup dimension (n). They outline the boundaries inside which the method variability is taken into account steady. Factors exterior these limits sign potential issues.

- Higher Management Restrict (UCL): R-bar * D4

- Decrease Management Restrict (LCL): R-bar * D3 (Word: LCL may be 0 for small pattern sizes)

- Heart Line (CL): R-bar

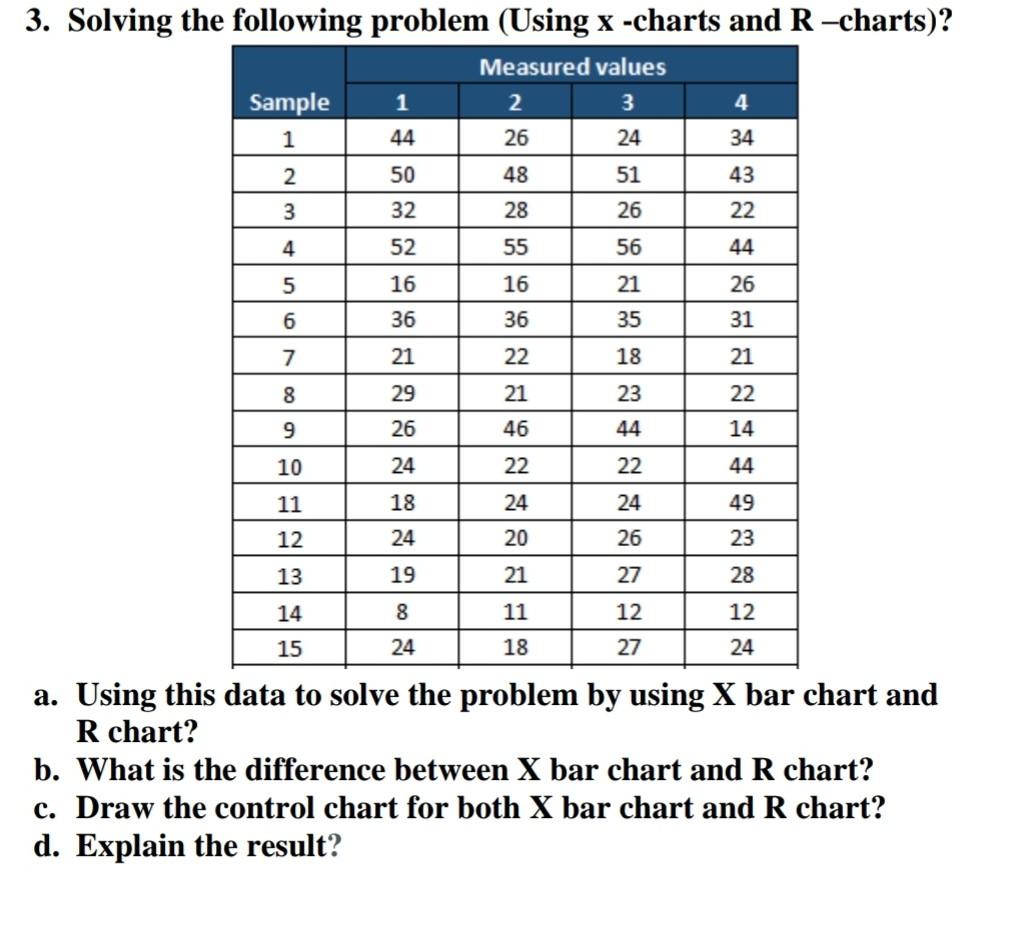

Instance Downside 1: Manufacturing Bolts

A producing plant produces bolts. Samples of 5 bolts are taken each hour for 20 hours. The next ranges (in millimeters) have been recorded:

| Hour | Vary (R) |

|---|---|

| 1 | 0.15 |

| 2 | 0.12 |

| 3 | 0.18 |

| 4 | 0.10 |

| 5 | 0.14 |

| 6 | 0.16 |

| 7 | 0.13 |

| 8 | 0.11 |

| 9 | 0.17 |

| 10 | 0.15 |

| 11 | 0.19 |

| 12 | 0.14 |

| 13 | 0.12 |

| 14 | 0.16 |

| 15 | 0.13 |

| 16 | 0.11 |

| 17 | 0.18 |

| 18 | 0.15 |

| 19 | 0.10 |

| 20 | 0.14 |

Resolution:

-

Calculate the common vary (R-bar): Sum all of the ranges and divide by the variety of subgroups (20).

R-bar = (0.15 + 0.12 + 0.18 + … + 0.14) / 20 = 0.142 mm

-

Discover the management chart constants: For n = 5, from a management chart constants desk, we discover d2 ≈ 2.326, D3 ≈ 0, and D4 ≈ 1.628.

-

Calculate the management limits:

- UCL = R-bar D4 = 0.142 1.628 ≈ 0.231 mm

- LCL = R-bar D3 = 0.142 0 = 0 mm

-

Assemble the R-chart: Plot the person ranges in opposition to the hour quantity, together with the middle line (R-bar = 0.142 mm) and the management limits (UCL = 0.231 mm, LCL = 0 mm).

-

Interpretation: All of the vary values fall inside the management limits. This means that the method variability is steady and below management.

Instance Downside 2: Packaging Course of

An organization packages espresso beans into 1-pound baggage. They take samples of 4 baggage each hour for 12 hours. The ranges of the weights (in ounces) are:

| Hour | Vary (R) |

|---|---|

| 1 | 0.25 |

| 2 | 0.18 |

| 3 | 0.32 |

| 4 | 0.20 |

| 5 | 0.28 |

| 6 | 0.15 |

| 7 | 0.35 |

| 8 | 0.22 |

| 9 | 0.27 |

| 10 | 0.19 |

| 11 | 0.40 |

| 12 | 0.24 |

Resolution:

-

Calculate R-bar: R-bar = (0.25 + 0.18 + 0.32 + … + 0.24) / 12 = 0.245 oz

-

Discover management chart constants: For n = 4, d2 ≈ 2.059, D3 ≈ 0, and D4 ≈ 2.282.

-

Calculate management limits:

- UCL = 0.245 * 2.282 ≈ 0.559 oz

- LCL = 0.245 * 0 = 0 oz

-

Assemble the R-chart: Plot the information, middle line, and management limits.

-

Interpretation: Whereas most factors are inside the limits, hour 7 and hour 11 present ranges exceeding the UCL. This means elevated variability within the packaging course of throughout these hours. An investigation into the reason for this elevated variability (e.g., machine malfunction, operator error) is critical.

Instance Downside 3: Out-of-Management Factors and Subsequent Motion

Let’s take into account the bolt manufacturing instance once more, however with a modification. Suppose that in hour 15, a big machine malfunction induced a spread of 0.40 mm.

Resolution:

-

Recalculate R-bar: Together with the brand new information level, R-bar would enhance considerably.

-

Re-calculate management limits: The UCL and CL would shift upwards.

-

Interpretation: The purpose at hour 15 would clearly be exterior the brand new UCL. This alerts an out-of-control situation, clearly indicating an issue with the method. The information level from hour 15 ought to be investigated and probably faraway from the calculation of R-bar and management limits, because it represents a particular reason for variation. After addressing the machine malfunction, new information ought to be collected to determine new management limits and make sure the course of is again in management.

Instance Downside 4: Small Pattern Sizes and LCL = 0

Think about a course of the place solely 2 measurements are taken per subgroup.

Resolution: For n=2, D3 = 0. This implies the LCL will all the time be 0 for an R-chart with a subgroup dimension of two. Whereas this may appear uncommon, it merely displays the truth that with solely two measurements, the minimal vary is all the time 0. The main focus shifts completely to monitoring the higher management restrict, in search of excessively giant ranges indicating elevated variability.

Conclusion:

R-charts are highly effective instruments for monitoring course of variability. By understanding the right way to calculate management limits, interpret the charts, and examine out-of-control factors, producers and different organizations can successfully enhance course of stability, cut back defects, and improve total high quality. Keep in mind that the effectiveness of R-charts will depend on correct information assortment, constant subgroup sizes, and an intensive understanding of the underlying course of. At all times examine factors exterior the management limits to determine and rectify the foundation causes of elevated variability. Additional evaluation, equivalent to X-bar charts, is perhaps essential to get a complete understanding of the method imply and variability. Utilizing each charts collectively offers a whole image of course of efficiency.

Closure

Thus, we hope this text has offered priceless insights into R-Chart Instance Issues with Options: Mastering Course of Variability Management. We respect your consideration to our article. See you in our subsequent article!