np chart vs p chart

Associated Articles: np chart vs p chart

Introduction

On this auspicious event, we’re delighted to delve into the intriguing matter associated to np chart vs p chart. Let’s weave fascinating data and supply contemporary views to the readers.

Desk of Content material

NP Chart vs. P Chart: Selecting the Proper Management Chart for Your Course of

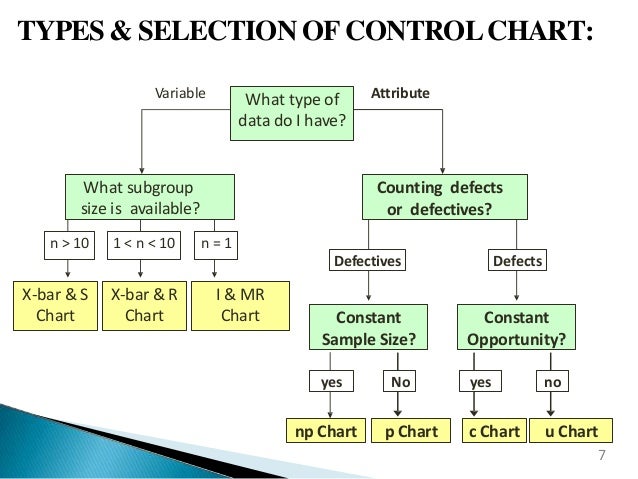

Management charts are indispensable instruments in statistical course of management (SPC), offering a visible illustration of course of stability and serving to determine potential sources of variation. Among the many numerous management charts, the NP chart and the P chart are often used to watch the proportion of nonconforming items in a course of. Nevertheless, they differ of their utility and the kind of knowledge they require. Understanding these variations is essential for choosing the suitable chart and successfully analyzing course of efficiency. This text delves into the nuances of NP charts and P chart, evaluating their traits, suitability, and offering sensible examples to assist of their utility.

Understanding the Fundamentals: Nonconformities vs. Proportions

Earlier than diving into the specifics of every chart, it is important to make clear the important thing distinction between the info they make the most of:

-

NP Chart: This chart displays the quantity of nonconforming items in a pattern of fixed measurement. The "N" represents the fixed pattern measurement, and "P" represents the proportion of nonconforming items. The chart tracks the precise depend of defects, making it appropriate for conditions the place the pattern measurement stays constant throughout all subgroups.

-

P Chart: This chart displays the proportion of nonconforming items in a pattern of variable measurement. It focuses on the proportion of faulty objects inside every pattern, whatever the pattern’s measurement. This flexibility makes it appropriate for situations the place sampling sizes fluctuate resulting from course of constraints or sensible limitations.

Information Necessities and Chart Development:

The development of every chart entails calculating management limits based mostly on the historic knowledge of the method. Let’s break down the method for every:

NP Chart:

-

Information Assortment: Acquire knowledge for ‘okay’ subgroups, every of measurement ‘N’. For every subgroup, report the variety of nonconforming items (nᵢ).

-

Calculate the Common Variety of Nonconforming Items: Calculate the common variety of nonconforming items (np̄) throughout all subgroups:

np̄ = Σnᵢ / okay

-

Calculate the Common Proportion of Nonconforming Items: Calculate the common proportion of nonconforming items (p̄):

p̄ = np̄ / N

-

Calculate the Management Limits: The management limits for the NP chart are:

- Higher Management Restrict (UCL): np̄ + 3√(Np̄(1-p̄))

- Middle Line (CL): np̄

- Decrease Management Restrict (LCL): np̄ – 3√(Np̄(1-p̄)) (LCL shouldn’t be lower than zero. Whether it is, set LCL = 0)

-

Plot the Information: Plot the variety of nonconforming items (nᵢ) for every subgroup on the chart, together with the calculated management limits and middle line.

P Chart:

-

Information Assortment: Acquire knowledge for ‘okay’ subgroups, every of variable measurement (Nᵢ). For every subgroup, report the variety of nonconforming items (nᵢ).

-

Calculate the Common Proportion of Nonconforming Items: Calculate the common proportion of nonconforming items (p̄) throughout all subgroups:

p̄ = Σnᵢ / ΣNᵢ

-

Calculate the Management Limits: The management limits for the P chart are:

- Higher Management Restrict (UCL): p̄ + 3√(p̄*(1-p̄)/Nᵢ) (for every subgroup i)

- Middle Line (CL): p̄

- Decrease Management Restrict (LCL): p̄ – 3√(p̄*(1-p̄)/Nᵢ) (for every subgroup i) (LCL shouldn’t be lower than zero. Whether it is, set LCL = 0)

-

Plot the Information: Plot the proportion of nonconforming items (nᵢ/Nᵢ) for every subgroup on the chart, together with the calculated management limits and middle line. Observe that the management limits will fluctuate for every subgroup as a result of variable pattern measurement.

Selecting Between NP Chart and P Chart:

The selection between an NP chart and a P chart hinges on the consistency of the pattern measurement:

-

Use an NP chart when: The pattern measurement (N) stays fixed throughout all subgroups. This simplifies the calculation of management limits and makes the interpretation extra easy. Examples embrace inspecting a hard and fast variety of objects produced per hour or day.

-

Use a P chart when: The pattern measurement (Nᵢ) varies throughout subgroups. This flexibility accommodates conditions the place sampling sizes are dictated by components like manufacturing batch sizes, availability of sources, or time constraints. Examples embrace inspecting different-sized batches of incoming supplies or randomly sampling all through the day with various pattern sizes.

Benefits and Disadvantages:

| Characteristic | NP Chart | P Chart |

|---|---|---|

| Pattern Dimension | Fixed | Variable |

| Information Plotted | Variety of nonconforming items | Proportion of nonconforming items |

| Management Limits | Fixed for all subgroups | Variable for every subgroup |

| Simplicity | Simpler to interpret and calculate limits | Extra complicated calculations and interpretations |

| Applicability | Fixed pattern measurement processes | Variable pattern measurement processes |

| Sensitivity | Could be much less delicate to small shifts | Extra delicate to small shifts in proportion |

Sensible Examples:

Instance 1 (NP Chart): A producing plant produces 100 widgets per hour. Each hour, a pattern of 20 widgets is inspected for defects. An NP chart could be acceptable to watch the variety of faulty widgets per hour.

Instance 2 (P Chart): A top quality management inspector randomly samples incoming shipments of parts. The cargo sizes fluctuate significantly. A P chart is acceptable to watch the proportion of faulty parts in every cargo, whatever the cargo measurement.

Past the Fundamentals: Concerns for Efficient Implementation

-

Adequate Information: Each charts require adequate historic knowledge to precisely estimate the method parameters and set up dependable management limits. Usually, at the very least 20-25 subgroups are really helpful.

-

Course of Stability: The charts assume the method is secure (in management) when the info is collected to ascertain the management limits. If the method is unstable, the calculated limits is not going to be dependable.

-

Out-of-Management Factors: Factors falling exterior the management limits point out potential course of instability and warrant investigation. Nevertheless, it is essential to research the reason for the out-of-control factors and never merely regulate the method based mostly on the chart alone.

-

Subgroup Choice: The selection of subgroups is vital. Subgroups needs to be homogenous and consultant of the method. Inappropriate subgrouping can result in deceptive outcomes.

-

Software program Instruments: Statistical software program packages like Minitab, JMP, and R supply highly effective instruments for creating and analyzing NP and P charts, automating calculations and offering superior evaluation capabilities.

Conclusion:

The NP chart and the P chart are precious instruments for monitoring the proportion of nonconforming items in a course of. The selection between them relies upon totally on the consistency of the pattern measurement. The NP chart is easier to make use of when the pattern measurement is fixed, whereas the P chart supplies the flexibleness to deal with variable pattern sizes. Cautious consideration of knowledge necessities, chart development, and interpretation is essential for efficient utility and correct course of monitoring. By understanding the strengths and limitations of every chart, high quality management professionals can choose essentially the most acceptable software for his or her particular wants, resulting in improved course of management and lowered defects.

Closure

Thus, we hope this text has supplied precious insights into np chart vs p chart. We hope you discover this text informative and useful. See you in our subsequent article!