Navigating the Labyrinth: A Complete Information to the Materials Assessment Board (MRB) Course of Flowchart

Associated Articles: Navigating the Labyrinth: A Complete Information to the Materials Assessment Board (MRB) Course of Flowchart

Introduction

On this auspicious event, we’re delighted to delve into the intriguing subject associated to Navigating the Labyrinth: A Complete Information to the Materials Assessment Board (MRB) Course of Flowchart. Let’s weave fascinating data and supply contemporary views to the readers.

Desk of Content material

Navigating the Labyrinth: A Complete Information to the Materials Assessment Board (MRB) Course of Flowchart

The Materials Assessment Board (MRB) course of is a important part of high quality administration programs in manufacturing and different industries. It is a structured method to evaluating non-conforming supplies, merchandise, or processes, figuring out their root causes, and deciding on applicable corrective and preventive actions (CAPA). A transparent understanding of this course of, typically visualized by way of a flowchart, is essential for sustaining product high quality, minimizing waste, and guaranteeing regulatory compliance. This text delves deep into the MRB course of flowchart, explaining every stage intimately and offering sensible examples for example its software.

I. Understanding the Function of the MRB Course of

Earlier than diving into the flowchart, it is important to grasp the core goals of an MRB:

- Determine and Examine Non-Conforming Objects: The method begins with the detection of a non-conformity – a fabric, product, or course of that deviates from specified necessities. This might vary from minor defects to important failures.

- Decide Root Trigger Evaluation (RCA): A radical investigation is performed to pinpoint the underlying causes for the non-conformity. This typically includes analyzing knowledge, interviewing personnel, and reviewing processes. Methods just like the 5 Whys, fishbone diagrams, and fault tree evaluation are generally employed.

- Consider the Impression of Non-Conformity: The MRB assesses the potential impression of the non-conforming merchandise on product high quality, security, and buyer satisfaction.

- Determine on Disposition: Based mostly on the RCA and impression evaluation, the MRB decides on the suitable disposition of the non-conforming merchandise. Choices embrace rework, restore, scrap, concession, or quarantine.

- Implement Corrective and Preventive Actions (CAPA): To forestall recurrence, the MRB develops and implements CAPA. This may occasionally contain course of enhancements, coaching, gear upgrades, or modifications to provider specs.

- Doc the Complete Course of: Meticulous documentation is essential for traceability, auditing, and steady enchancment. All findings, selections, and actions taken are meticulously recorded.

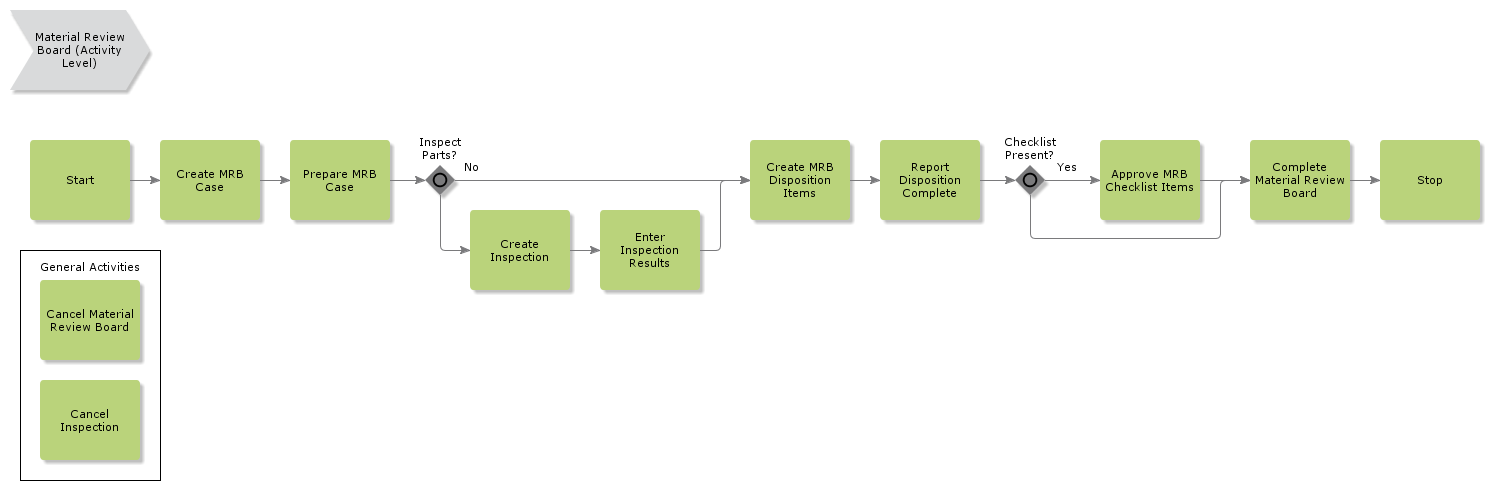

II. The Materials Assessment Board (MRB) Course of Flowchart

The next flowchart represents a typical MRB course of. Variations might exist relying on the precise business, firm, and complexity of the non-conformity.

[Start] --> [Non-Conforming Material/Product/Process Identified] --> [Initial Notification & Quarantine] --> [MRB Convened] --> [Investigation & Root Cause Analysis (RCA)] --> [Impact Assessment] --> [Disposition Decision] --> [Corrective & Preventive Actions (CAPA) Implementation] --> [Verification & Validation] --> [MRB Closure] --> [Documentation & Archiving] --> [End]III. Detailed Clarification of Every Stage

Let’s break down every stage of the flowchart intimately:

1. Non-Conforming Materials/Product/Course of Recognized: That is the set off for your entire MRB course of. Non-conformities may be detected at numerous phases, together with incoming inspection, in-process inspection, ultimate inspection, and even buyer complaints. The detection technique might contain visible inspection, testing, or knowledge evaluation.

2. Preliminary Notification & Quarantine: Upon discovery, the non-conforming merchandise is instantly quarantined to forestall additional processing or use. A proper notification is issued, together with particulars in regards to the non-conformity, location, amount, and any preliminary observations.

3. MRB Convened: The MRB, sometimes composed of representatives from numerous departments (e.g., high quality, engineering, manufacturing, buying), is convened to assessment the case. The assembly is chaired by a chosen chief, typically a high quality supervisor.

4. Investigation & Root Trigger Evaluation (RCA): It is a essential stage the place the group meticulously investigates the foundation explanation for the non-conformity. Varied instruments and methods are employed, together with:

- 5 Whys: Repeatedly asking "why" to uncover the underlying causes.

- Fishbone Diagram (Ishikawa Diagram): A visible instrument to determine potential causes categorized by elements like supplies, strategies, manpower, equipment, measurement, and atmosphere.

- Fault Tree Evaluation: A top-down method to figuring out potential causes of a failure.

- Pareto Evaluation: Focuses on probably the most important contributing elements.

5. Impression Evaluation: The MRB assesses the potential impression of the non-conformity on product high quality, security, buyer satisfaction, and regulatory compliance. This evaluation informs the disposition resolution.

6. Disposition Resolution: Based mostly on the RCA and impression evaluation, the MRB decides on the suitable disposition of the non-conforming merchandise. Attainable inclinations embrace:

- Rework: Correcting the defect and bringing the merchandise again to conformance.

- Restore: Making essential repairs to revive performance.

- Scrap: Discarding the merchandise because it’s uneconomical or unattainable to deliver it again to conformance.

- Concession: Accepting the non-conformity below particular situations, typically with buyer approval.

- Quarantine: Quickly setting apart the merchandise pending additional investigation or resolution.

7. Corrective & Preventive Actions (CAPA) Implementation: The MRB identifies and implements CAPA to forestall recurrence of the non-conformity. This may occasionally contain course of enhancements, worker coaching, gear upgrades, or modifications to provider specs.

8. Verification & Validation: After implementing CAPA, the effectiveness of the actions is verified and validated to make sure that the issue is resolved and won’t reoccur.

9. MRB Closure: As soon as all actions are accomplished and verified, the MRB formally closes the case.

10. Documentation & Archiving: All facets of the MRB course of, together with the preliminary notification, investigation findings, RCA, disposition resolution, CAPA, and verification outcomes, are meticulously documented and archived for future reference and audits.

IV. Instance State of affairs

Let’s contemplate a state of affairs the place a batch of metallic parts fails a tensile power take a look at throughout incoming inspection. The MRB can be convened, and the next steps can be taken:

- Identification: The failed parts are recognized and quarantined.

- Notification: A proper notification is shipped to related departments.

- Investigation: The MRB investigates, utilizing a fishbone diagram to discover potential causes (e.g., defective uncooked materials, incorrect warmth therapy, machine malfunction).

- RCA: The foundation trigger is recognized as a defective warmth therapy course of on the provider.

- Impression Evaluation: The impression is assessed as doubtlessly important, because it might have an effect on the structural integrity of the ultimate product.

- Disposition: The parts are scrapped.

- CAPA: The MRB works with the provider to rectify their warmth therapy course of and implement stricter high quality management measures.

- Verification: Subsequent batches of parts are examined to confirm the effectiveness of the CAPA.

- Closure: The MRB closes the case after profitable verification.

- Documentation: All the course of is documented and archived.

V. Conclusion

The Materials Assessment Board course of, as visualized by way of a flowchart, is a scientific method to managing non-conformities. By following this structured course of, organizations can successfully determine root causes, implement corrective and preventive actions, and make sure the high quality and security of their merchandise. A well-defined MRB course of is just not merely a compliance requirement; it is a important instrument for steady enchancment and sustaining a powerful high quality administration system. The detailed rationalization and instance supplied on this article ought to help organizations in successfully implementing and using their very own MRB course of, resulting in enhanced product high quality and diminished waste. Common assessment and optimization of the MRB course of are important to make sure its continued effectiveness.

Closure

Thus, we hope this text has supplied helpful insights into Navigating the Labyrinth: A Complete Information to the Materials Assessment Board (MRB) Course of Flowchart. We recognize your consideration to our article. See you in our subsequent article!