Demystifying the p-Chart: A Complete Instance Drawback and Resolution

Associated Articles: Demystifying the p-Chart: A Complete Instance Drawback and Resolution

Introduction

On this auspicious event, we’re delighted to delve into the intriguing subject associated to Demystifying the p-Chart: A Complete Instance Drawback and Resolution. Let’s weave attention-grabbing data and supply contemporary views to the readers.

Desk of Content material

Demystifying the p-Chart: A Complete Instance Drawback and Resolution

Statistical Course of Management (SPC) is a vital software for sustaining high quality and effectivity in numerous industries. Among the many many SPC charts, the p-chart holds a big place, notably when coping with the proportion of nonconforming models in a pattern. This text delves into an in depth instance downside involving a p-chart, explaining the methodology, calculations, and interpretations concerned. We are going to dissect the issue step-by-step, clarifying widespread misconceptions and offering a sturdy understanding of this highly effective statistical software.

Understanding the p-Chart

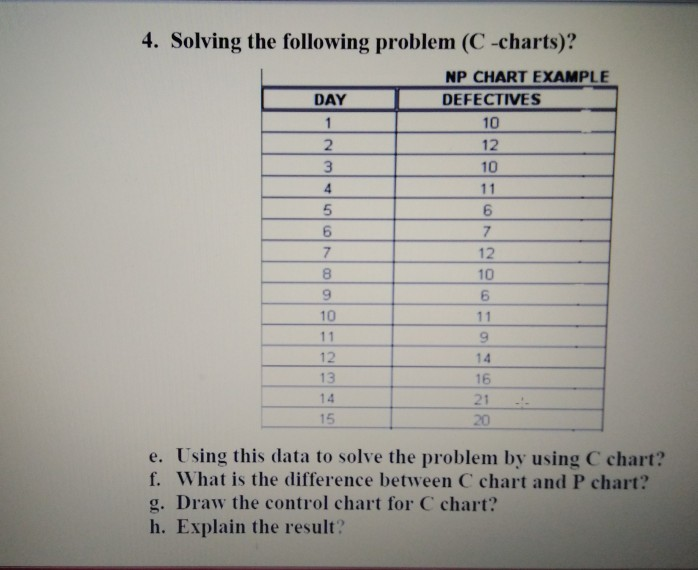

The p-chart is a management chart used to watch the proportion (p) of faulty or nonconforming models in a pattern. Not like the c-chart which tracks the variety of defects, the p-chart focuses on the proportion of defects relative to the pattern measurement. This makes it ultimate for conditions the place the pattern measurement varies from one pattern to a different. The chart visually shows the proportion of defects over time, permitting for the identification of traits, shifts, and strange variations which may sign course of instability.

Key Parts of a p-Chart:

- Heart Line (CL): Represents the typical proportion of nonconforming models over all samples.

- Higher Management Restrict (UCL): The higher boundary past which a pattern proportion is taken into account statistically unlikely if the method is in management.

- Decrease Management Restrict (LCL): The decrease boundary beneath which a pattern proportion is taken into account statistically unlikely if the method is in management.

Instance Drawback: Manufacturing of Circuit Boards

Let’s think about a producing firm producing circuit boards. The corporate randomly samples 50 circuit boards every day to test for defects. The information collected over 20 days is as follows:

| Day | Pattern Dimension (n) | Variety of Defects (d) | Proportion of Defects (p) |

|---|---|---|---|

| 1 | 50 | 2 | 0.04 |

| 2 | 50 | 3 | 0.06 |

| 3 | 50 | 1 | 0.02 |

| 4 | 50 | 4 | 0.08 |

| 5 | 50 | 2 | 0.04 |

| 6 | 50 | 5 | 0.10 |

| 7 | 50 | 3 | 0.06 |

| 8 | 50 | 2 | 0.04 |

| 9 | 50 | 1 | 0.02 |

| 10 | 50 | 4 | 0.08 |

| 11 | 50 | 3 | 0.06 |

| 12 | 50 | 2 | 0.04 |

| 13 | 50 | 1 | 0.02 |

| 14 | 50 | 0 | 0.00 |

| 15 | 50 | 2 | 0.04 |

| 16 | 50 | 3 | 0.06 |

| 17 | 50 | 4 | 0.08 |

| 18 | 50 | 2 | 0.04 |

| 19 | 50 | 1 | 0.02 |

| 20 | 50 | 3 | 0.06 |

Calculating the Management Limits:

-

Calculate the typical proportion of defects (p-bar):

That is the sum of all proportions of defects divided by the variety of samples.

p-bar = (0.04 + 0.06 + 0.02 + … + 0.06) / 20 = 0.0435

-

Calculate the usual deviation of the proportion (σp):

The method for the usual deviation of the proportion is:

σp = √[p-bar(1 – p-bar) / n]

The place ‘n’ is the pattern measurement (50 on this case).

σp = √[0.0435(1 – 0.0435) / 50] = 0.0286

-

Calculate the Higher Management Restrict (UCL) and Decrease Management Restrict (LCL):

UCL = p-bar + 3σp = 0.0435 + 3(0.0286) = 0.1293

LCL = p-bar – 3σp = 0.0435 – 3(0.0286) = -0.0423For the reason that LCL is detrimental, we set it to 0, as a proportion can’t be detrimental. This can be a widespread incidence when coping with small proportions of defects.

Establishing the p-Chart:

Now, we are able to plot the info on a p-chart with the middle line (CL) at 0.0435, UCL at 0.1293, and LCL at 0.

Decoding the Outcomes:

By analyzing the p-chart, we are able to visually assess whether or not the method is in management. If any factors fall outdoors the management limits, or if there are patterns (traits, runs) throughout the management limits, it means that the method is uncontrolled and requires investigation. In our instance, all the info factors fall throughout the management limits, indicating that the manufacturing technique of circuit boards is statistically in management in regards to the proportion of defects.

Addressing Potential Points and Additional Evaluation:

Though the method seems in management on this instance, a number of factors warrant additional dialogue:

-

Small Pattern Sizes: Whereas we used a pattern measurement of fifty, smaller pattern sizes can result in wider management limits, decreasing the chart’s sensitivity to small shifts within the course of. Bigger pattern sizes usually enhance the accuracy of the p-chart.

-

Non-constant Pattern Sizes: The p-chart assumes a continuing pattern measurement. If the pattern measurement varies considerably, changes to the management restrict calculations are needed, usually utilizing a weighted common.

-

Information Distribution: The p-chart assumes that the info follows a binomial distribution. If this assumption is violated, the management limits will not be correct.

-

Course of Functionality: The p-chart solely signifies whether or not the method is in management. It would not assess whether or not the method is able to assembly specs. Extra evaluation, resembling course of functionality indices (Cpk, Pp), could be wanted to find out if the defect fee meets the required requirements.

-

Particular Trigger Variation: Whereas no factors fall outdoors the boundaries on this instance, an intensive investigation of the info needs to be carried out. For example, a run of a number of consecutive factors above or beneath the centerline may point out a possible downside even when throughout the limits. This requires additional investigation into the method parameters.

Conclusion:

The p-chart is a invaluable software for monitoring the proportion of nonconforming models in a course of. This detailed instance downside demonstrated the steps concerned in establishing and decoding a p-chart. Nonetheless, it is essential to keep in mind that the p-chart is only one piece of the standard management puzzle. A complete strategy entails understanding the method, deciding on acceptable pattern sizes, contemplating the underlying assumptions, and decoding the outcomes throughout the broader context of the manufacturing course of. By rigorously contemplating these elements, the p-chart could be successfully used to enhance course of stability and high quality. Additional investigation into potential particular causes of variation, even inside management limits, is really helpful for a really sturdy high quality management system. The instance highlighted the significance of steady monitoring and enchancment in sustaining a secure and environment friendly manufacturing course of.

Closure

Thus, we hope this text has offered invaluable insights into Demystifying the p-Chart: A Complete Instance Drawback and Resolution. We hope you discover this text informative and useful. See you in our subsequent article!