Decoding the T-Jet Spray Nozzle Chart: A Complete Information for Optimum Spray Software

Associated Articles: Decoding the T-Jet Spray Nozzle Chart: A Complete Information for Optimum Spray Software

Introduction

With enthusiasm, let’s navigate by way of the intriguing matter associated to Decoding the T-Jet Spray Nozzle Chart: A Complete Information for Optimum Spray Software. Let’s weave fascinating data and supply recent views to the readers.

Desk of Content material

Decoding the T-Jet Spray Nozzle Chart: A Complete Information for Optimum Spray Software

The T-Jet spray nozzle, a ubiquitous software in varied industries, calls for an intensive understanding for attaining environment friendly and efficient spraying. Its efficiency hinges considerably on correct nozzle choice, a process vastly simplified by way of a T-Jet spray nozzle chart. This chart, a seemingly easy desk, offers essential data enabling customers to optimize spray patterns, circulate charges, and total software effectivity. This text delves deep into the intricacies of the T-Jet spray nozzle chart, explaining its parts, deciphering its knowledge, and highlighting its sensible functions throughout various fields.

Understanding the T-Jet Nozzle System:

Earlier than diving into the chart itself, it is important to grasp the elemental rules behind T-Jet nozzles. These nozzles are characterised by their distinctive design, sometimes that includes a swirling inside circulate that creates a hole cone spray sample. This swirling motion contributes to a number of key benefits:

-

Uniform Protection: The hole cone spray sample ensures constant software throughout the goal space, minimizing overlaps and gaps. That is significantly essential in functions requiring even distribution, resembling pesticide spraying or portray.

-

Elevated Atomization: The swirling movement enhances the atomization of the liquid, creating finer droplets. This improved atomization results in higher penetration, sooner drying occasions, and diminished drift.

-

Adjustable Spray Traits: T-Jet nozzles are sometimes out there in varied sizes and configurations, permitting customers to tailor the spray sample and circulate charge to particular wants. This adjustability is a key characteristic mirrored within the spray nozzle chart.

Deciphering the T-Jet Spray Nozzle Chart:

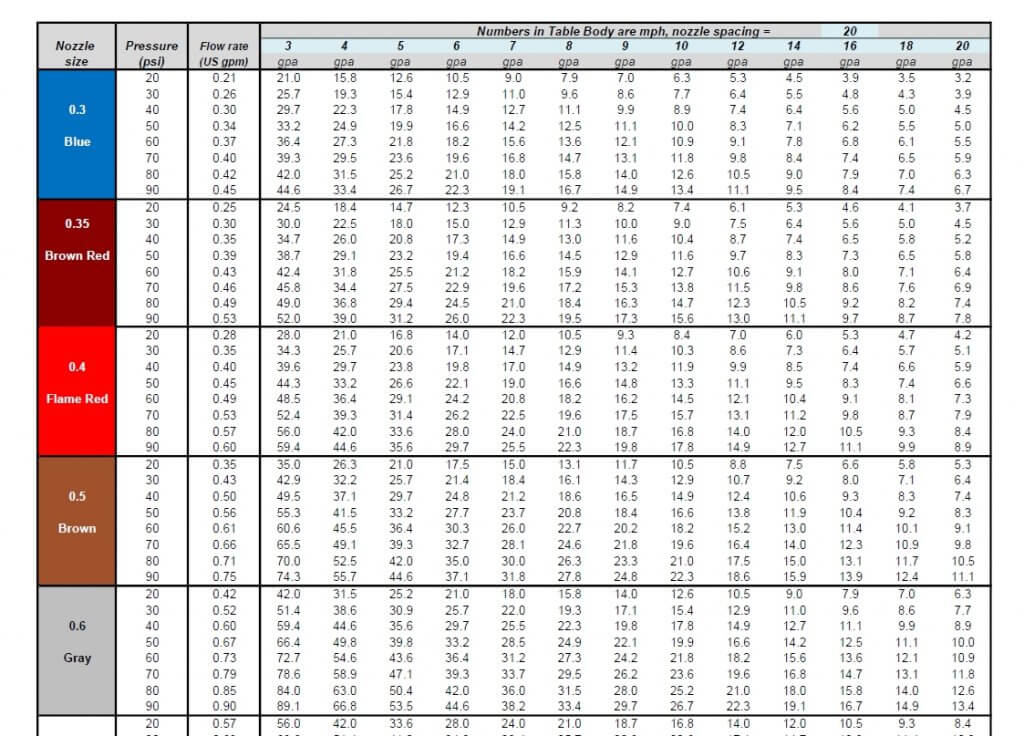

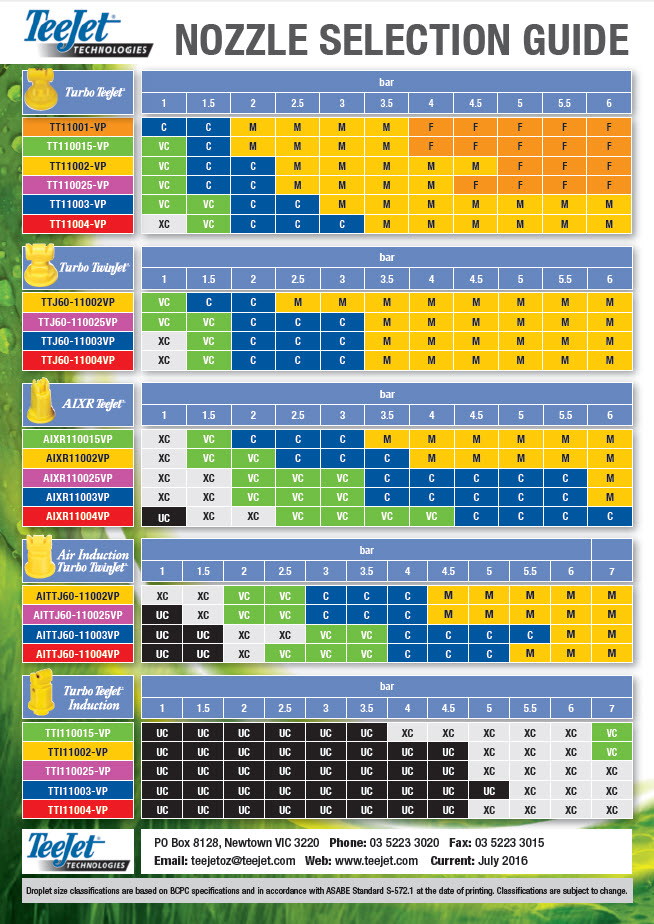

A typical T-Jet spray nozzle chart is organized in a tabular format, presenting key parameters for a spread of nozzle sizes and configurations. Whereas the precise structure may range barely between producers, the elemental data stays constant. Key parameters sometimes included are:

-

Nozzle Dimension (e.g., 8001, 8002, and so on.): This can be a distinctive identifier for every nozzle, indicating its inside geometry and circulate traits. Totally different numbers symbolize completely different nozzle sizes impacting the circulate charge and spray sample.

-

Circulate Price (GPM or LPM): This specifies the quantity of liquid the nozzle discharges per unit time (gallons per minute or liters per minute). This worth is normally supplied for a particular working stress.

-

Working Stress (PSI or Bar): The stress at which the nozzle is designed to function optimally. Deviating considerably from the advisable stress can compromise spray sample uniformity and effectivity.

-

Spray Angle (levels): This means the angular width of the spray sample produced by the nozzle. Frequent spray angles vary from 65 to 110 levels, with wider angles protecting bigger areas however doubtlessly sacrificing droplet dimension uniformity.

-

Droplet Dimension (µm): This parameter is essential for functions delicate to droplet dimension, resembling pesticide software the place smaller droplets improve penetration and scale back drift. The chart may present a median droplet dimension or a spread.

-

Protection Price (acres/hour or hectares/hour): This worth signifies the realm the nozzle can cowl per unit time at a given working stress and velocity. That is significantly related for large-scale functions.

-

Nozzle Materials: The fabric of the nozzle (e.g., stainless-steel, brass, plastic) can also be usually specified, indicating its compatibility with completely different chemical substances and working situations. Materials choice influences the nozzle’s sturdiness and resistance to corrosion.

Decoding the Information and Choosing the Proper Nozzle:

Utilizing the T-Jet spray nozzle chart successfully requires understanding how these parameters work together. As an example, growing the working stress usually will increase the circulate charge however may also have an effect on droplet dimension and spray angle. The choice course of sometimes includes the next steps:

-

Decide Software Necessities: Establish the precise wants of the appliance, together with the specified protection space, spray sample, droplet dimension, and the kind of liquid being sprayed.

-

Choose the Applicable Nozzle Dimension: Based mostly on the appliance necessities and the chart knowledge, choose a nozzle dimension that delivers the specified circulate charge and spray angle on the supposed working stress.

-

Calculate Required Stress: Be certain that the chosen nozzle operates inside its advisable stress vary. Inadequate stress will end in poor atomization and uneven protection, whereas extreme stress can result in untimely put on and tear.

-

Confirm Protection Price: Test the protection charge to make sure it aligns with the specified software velocity and effectivity. Adjusting the journey velocity or nozzle spacing can compensate for variations in protection charge.

-

Contemplate Droplet Dimension: Pay shut consideration to the droplet dimension, particularly in functions the place drift or penetration is a priority. Smaller droplets are usually most well-liked for functions requiring higher penetration however could also be extra prone to float.

Purposes Throughout Industries:

The flexibility of T-Jet spray nozzles makes them invaluable throughout a variety of industries:

-

Agriculture: Pesticide software, herbicide spraying, fertilizer distribution. Correct and uniform software is essential for maximizing effectiveness and minimizing environmental affect.

-

Horticulture: Irrigation, nutrient software, pest management. The adjustable spray traits permit for focused software to particular vegetation or areas.

-

Industrial Coating: Portray, priming, sealing. The constant spray sample ensures uniform coating thickness and minimizes defects.

-

Cleansing and Sanitation: Disinfectant software, floor cleansing. The high-quality atomization enhances cleansing effectivity and reduces chemical consumption.

-

Hearth Suppression: Water distribution in fireplace suppression methods. The broad spray angle and excessive circulate charges are useful for protecting massive areas shortly.

Past the Chart: Components Influencing Nozzle Efficiency:

Whereas the T-Jet spray nozzle chart offers important data, different elements can affect nozzle efficiency:

-

Fluid Viscosity: The viscosity of the sprayed liquid impacts circulate charge and atomization. Increased viscosity liquids require larger working pressures to keep up optimum spray traits.

-

Fluid Temperature: Temperature adjustments may have an effect on viscosity and consequently affect the nozzle’s efficiency.

-

Nozzle Put on: Over time, nozzles can put on down, resulting in adjustments in circulate charge and spray sample. Common inspection and alternative are essential to keep up constant efficiency.

-

Nozzle Orientation: The angle at which the nozzle is positioned relative to the goal floor can have an effect on spray distribution.

Conclusion:

The T-Jet spray nozzle chart is an indispensable software for optimizing spray functions. By understanding its parts, deciphering its knowledge, and contemplating the varied elements influencing nozzle efficiency, customers can choose the suitable nozzle and obtain environment friendly, efficient, and constant spraying throughout various functions. Correct nozzle choice not solely enhances software high quality but additionally contributes to useful resource conservation and environmental safety. Investing time in understanding the T-Jet spray nozzle chart is an funding in improved effectivity and operational success.

Closure

Thus, we hope this text has supplied useful insights into Decoding the T-Jet Spray Nozzle Chart: A Complete Information for Optimum Spray Software. We hope you discover this text informative and useful. See you in our subsequent article!