Decoding the MS Spherical Pipe Weight Chart: A Complete Information

Associated Articles: Decoding the MS Spherical Pipe Weight Chart: A Complete Information

Introduction

With nice pleasure, we’ll discover the intriguing matter associated to Decoding the MS Spherical Pipe Weight Chart: A Complete Information. Let’s weave attention-grabbing data and supply recent views to the readers.

Desk of Content material

Decoding the MS Spherical Pipe Weight Chart: A Complete Information

Gentle metal (MS) spherical pipes are ubiquitous in building, manufacturing, and numerous different industries. Their versatility stems from their energy, sturdiness, and comparatively low price. Nevertheless, precisely calculating the load of those pipes is essential for materials estimation, transportation planning, and venture costing. This necessitates a radical understanding of MS spherical pipe weight charts and the components influencing their weight calculations. This text delves into the intricacies of those charts, offering a complete information for professionals and lovers alike.

Understanding the Fundamentals: Components Affecting MS Spherical Pipe Weight

The burden of an MS spherical pipe is not merely a matter of size. A number of key components contribute to its total mass:

-

Outer Diameter (OD): That is the measurement throughout the widest a part of the pipe’s exterior. A bigger OD inherently means extra materials and due to this fact, larger weight.

-

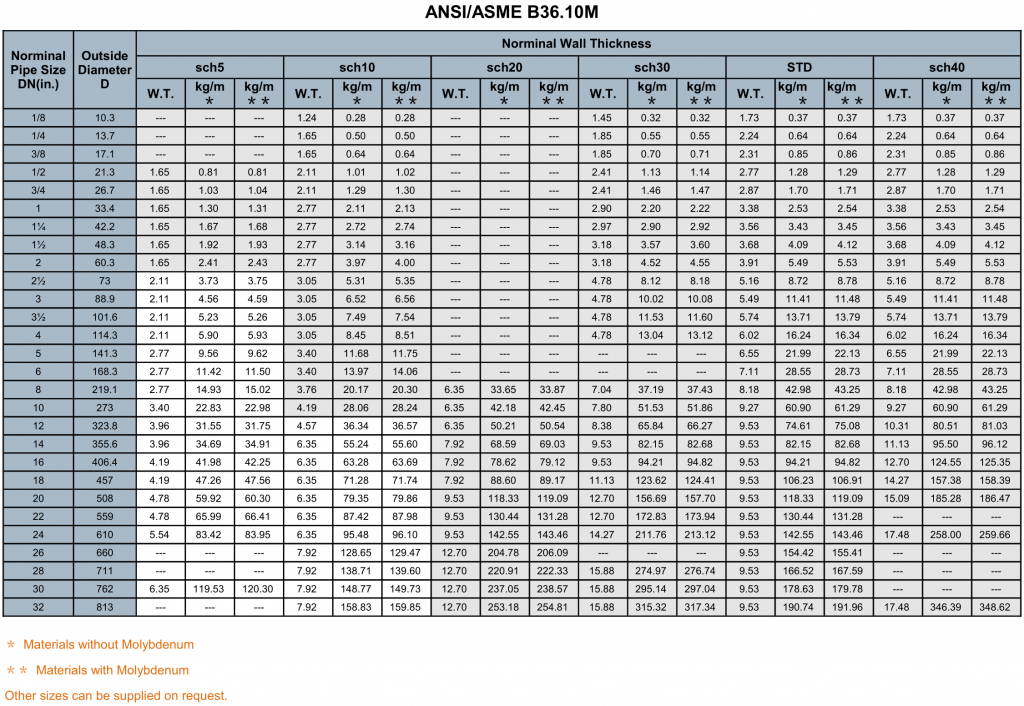

Wall Thickness (WT or Schedule): This refers back to the thickness of the pipe’s wall. Thicker partitions translate to a heavier pipe, even when the OD stays fixed. Totally different schedules (e.g., Schedule 40, Schedule 80) correspond to particular wall thicknesses. Understanding these schedules is vital for correct weight calculations.

-

Size: The size of the pipe instantly impacts its weight. An extended pipe, with all different components remaining the identical, will weigh extra.

-

Materials Density: Whereas sometimes constant for gentle metal (roughly 7850 kg/m³), variations in alloy composition can subtly have an effect on the density and due to this fact the load.

-

Manufacturing Tolerances: Slight variations in OD and WT can happen on account of manufacturing processes. These tolerances have to be thought of when working with exact weight calculations.

Decoding the MS Spherical Pipe Weight Chart

MS spherical pipe weight charts are tabular representations that correlate the above components to the load per unit size (sometimes kg/meter or lb/ft). These charts are invaluable instruments for shortly figuring out the load of a pipe given its OD, WT, and size. A typical chart might be structured as follows:

| Outer Diameter (OD) (mm/inches) | Wall Thickness (WT) (mm/inches) | Weight per Meter (kg/m) | Weight per Foot (lb/ft) |

|---|---|---|---|

| 21.3 mm (0.84 in) | 2.6 mm (0.10 in) | Approx. 1.0 kg/m | Approx. 0.67 lb/ft |

| 21.3 mm (0.84 in) | 3.2 mm (0.13 in) | Approx. 1.2 kg/m | Approx. 0.81 lb/ft |

| 26.7 mm (1.05 in) | 3.2 mm (0.13 in) | Approx. 1.6 kg/m | Approx. 1.08 lb/ft |

| …and so forth… | … | … | … |

Utilizing the Chart for Weight Calculation

To find out the whole weight of an MS spherical pipe utilizing the chart:

-

Determine the OD and WT: Precisely measure or acquire the specs for the pipe’s outer diameter and wall thickness.

-

Find the corresponding weight: Discover the intersection of the OD and WT within the chart to find out the load per unit size (kg/m or lb/ft).

-

Calculate the whole weight: Multiply the load per unit size by the whole size of the pipe. For instance, if the load per meter is 2.5 kg/m and the pipe size is 6 meters, the whole weight could be 15 kg (2.5 kg/m * 6 m).

Past the Normal Chart: Components to Contemplate

Whereas weight charts present a handy estimate, a number of components may necessitate a extra exact calculation:

-

Materials Grade: Variations within the gentle metal grade can barely affect density. Excessive-strength low-alloy (HSLA) steels, for example, may need a barely greater density.

-

Floor Coatings: Coatings like zinc galvanization add weight to the pipe. This extra weight must be factored into the general calculation.

-

Fittings and Equipment: The burden of flanges, elbows, and different fittings must be added to the whole weight of the piping system.

-

Corrosion Allowance: Over time, corrosion can scale back the wall thickness of a pipe. For long-term tasks, a corrosion allowance could be added to the load calculation to account for potential materials loss.

Calculating Weight Utilizing Formulation

For extra exact calculations, particularly when coping with non-standard pipe dimensions or materials properties, utilizing formulation is really useful. The most typical system is predicated on the pipe’s cross-sectional space and materials density:

*Weight = π/4 (OD² – ID²) L ρ**

The place:

- π: The mathematical fixed pi (roughly 3.14159)

- OD: Outer diameter of the pipe

- ID: Interior diameter of the pipe (OD – 2 * WT)

- L: Size of the pipe

- ρ: Density of the gentle metal (roughly 7850 kg/m³ or 0.283 lb/in³)

This system offers a extra correct weight calculation in comparison with relying solely on a chart, particularly when coping with variations in materials properties or uncommon pipe dimensions.

Functions and Significance of Correct Weight Calculation

Correct weight willpower is vital in a number of functions:

-

Transportation and Logistics: Realizing the precise weight is important for planning transportation, making certain secure loading, and complying with weight restrictions.

-

Structural Design: Correct weight calculations are very important for structural evaluation and design, making certain the steadiness and security of constructions using MS spherical pipes.

-

Price Estimation: Exact weight calculations are essential for correct materials price estimation and venture budgeting.

-

Stock Administration: Correct weight information facilitates environment friendly stock monitoring and administration.

-

Manufacturing Processes: Weight calculations are very important in manufacturing processes, resembling reducing, bending, and welding of pipes.

Conclusion:

MS spherical pipe weight charts are invaluable instruments for fast estimations, however understanding the underlying components and utilizing formulation for exact calculations is essential for numerous functions. Correct weight willpower ensures environment friendly venture planning, price management, and structural integrity. By combining chart utilization with formula-based calculations and contemplating all related components, professionals can confidently handle tasks involving MS spherical pipes, minimizing errors and maximizing effectivity. At all times check with the producer’s specs for probably the most correct information, as slight variations in materials properties and manufacturing tolerances can affect the ultimate weight.

Closure

Thus, we hope this text has offered useful insights into Decoding the MS Spherical Pipe Weight Chart: A Complete Information. We respect your consideration to our article. See you in our subsequent article!