Decoding the MS Pipe Schedule 40 Thickness Chart: A Complete Information

Associated Articles: Decoding the MS Pipe Schedule 40 Thickness Chart: A Complete Information

Introduction

With nice pleasure, we are going to discover the intriguing matter associated to Decoding the MS Pipe Schedule 40 Thickness Chart: A Complete Information. Let’s weave fascinating info and supply recent views to the readers.

Desk of Content material

Decoding the MS Pipe Schedule 40 Thickness Chart: A Complete Information

Delicate metal (MS) pipes are ubiquitous in varied industries, from building and plumbing to grease and fuel. Understanding the pipe’s schedule, significantly Schedule 40, is essential for choosing the proper pipe for a selected utility. This text delves deep into the MS pipe Schedule 40 thickness chart, explaining its significance, find out how to learn it, and its implications for design and engineering.

Understanding Pipe Schedules and Their Significance

A pipe schedule is a numerical designation indicating the pipe’s wall thickness relative to its nominal diameter. It does not immediately symbolize the precise wall thickness in millimeters or inches, however moderately a standardized ratio. Totally different schedules correspond to totally different wall thicknesses, providing various levels of strain resistance and structural integrity. Greater schedules (e.g., Schedule 80, 160) signify thicker partitions and consequently, increased strain scores. Schedule 40 is a extensively used normal, providing a stability between power and cost-effectiveness.

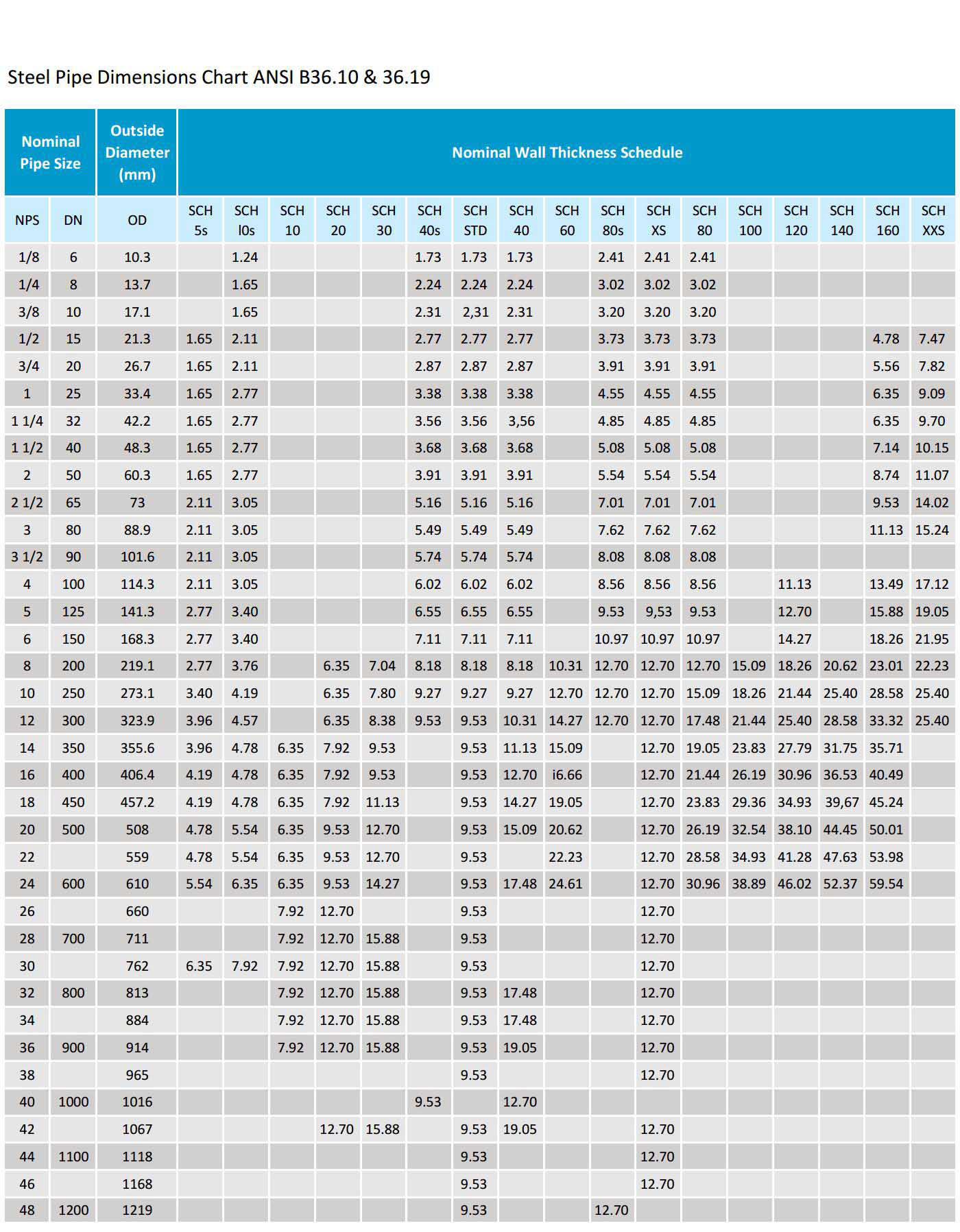

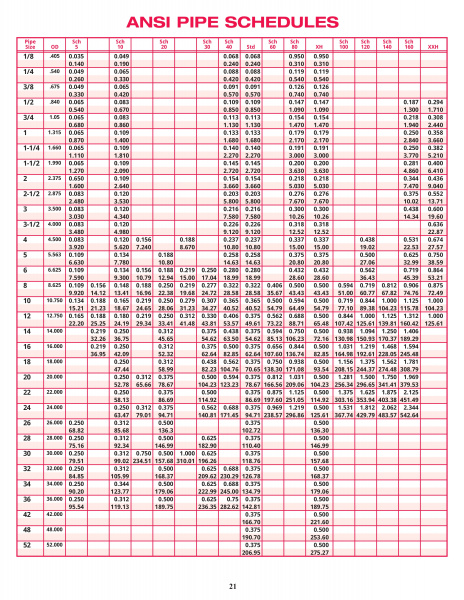

The MS Pipe Schedule 40 Thickness Chart: A Breakdown

The Schedule 40 thickness chart for MS pipes is not a single, universally fastened desk. The precise thickness varies barely relying on the manufacturing requirements (e.g., ASTM A53, ASTM A106) and the producer. Nevertheless, the variations are usually minor and inside acceptable tolerances. The chart sometimes presents knowledge in a tabular format, displaying the nominal pipe dimension (NPS), the skin diameter (OD), and the wall thickness (WT) for Schedule 40 pipes. The NPS is a nominal worth, and the precise outdoors diameter may differ barely.

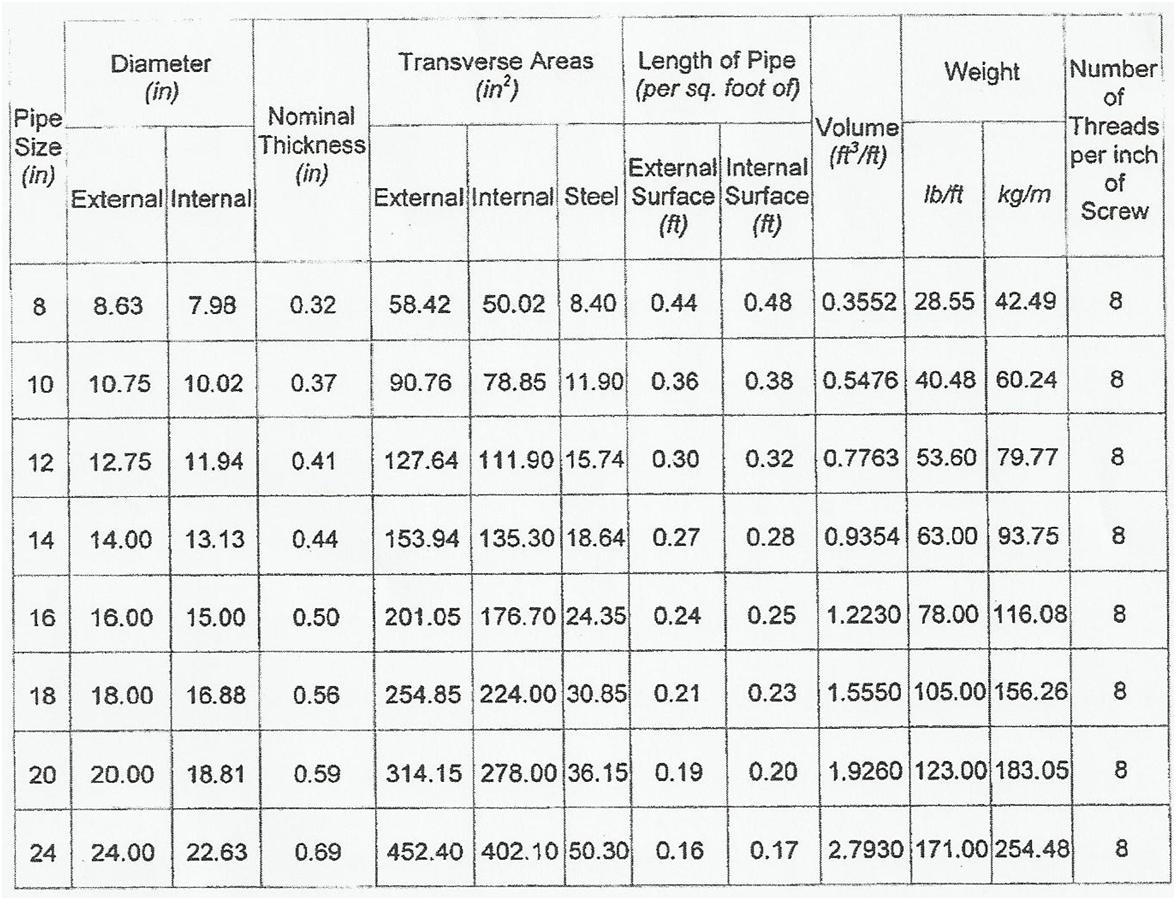

Key Parameters within the Chart:

-

Nominal Pipe Dimension (NPS): It is a standard designation representing the pipe’s approximate inner diameter. It is not the exact inner diameter, which is barely smaller as a result of wall thickness. NPS is often expressed in inches (e.g., 1/2", 1", 2", and so forth.).

-

Exterior Diameter (OD): That is the precise measured diameter of the pipe’s outer floor. It stays comparatively constant throughout totally different schedules for a given NPS, although minor variations may exist on account of manufacturing tolerances. OD can be sometimes expressed in inches.

-

Wall Thickness (WT): That is the essential parameter decided by the schedule. For Schedule 40, the wall thickness is considerably thicker than, say, Schedule 10, offering higher strain resistance and structural power. The WT is often given in inches or millimeters.

Decoding the Chart: An Instance

Let’s think about a hypothetical entry in a Schedule 40 MS pipe thickness chart:

| NPS | OD (inches) | WT (inches) |

|---|---|---|

| 2" | 2.375 | 0.154 |

This entry signifies {that a} 2-inch nominal pipe dimension (NPS) Schedule 40 MS pipe has an outdoor diameter (OD) of two.375 inches and a wall thickness (WT) of 0.154 inches. This info is significant for varied engineering calculations, together with figuring out the pipe’s inner diameter, weight, and strain capability.

Elements Affecting MS Pipe Schedule 40 Thickness:

Whereas the Schedule 40 designation supplies an ordinary, minor variations in thickness can happen on account of a number of components:

-

Manufacturing Tolerances: Manufacturing processes inherently introduce slight variations in dimensions. These variations are sometimes inside acceptable limits outlined by related requirements.

-

Materials Properties: The particular properties of the gentle metal used, reminiscent of its yield power and chemical composition, can affect the ultimate wall thickness.

-

Manufacturing Requirements: Totally different requirements (ASTM A53, ASTM A106, and so forth.) may specify barely totally different tolerances and necessities, resulting in minor variations in thickness.

Purposes of MS Pipe Schedule 40:

Schedule 40 MS pipes discover widespread functions on account of their sturdy building and cost-effectiveness. Some widespread functions embody:

- Water Provide Techniques: Carrying potable water in residential, industrial, and industrial settings.

- Drainage Techniques: Dealing with wastewater and drainage in varied functions.

- HVAC Techniques: Transporting heating and cooling fluids.

- Industrial Piping: Utilized in varied industrial processes for transporting fluids and gases, the place reasonable strain is concerned.

- Hearth Safety Techniques: In some circumstances, Schedule 40 pipes is likely to be utilized in hearth sprinkler methods.

Selecting the Proper Schedule:

The selection between totally different pipe schedules is determined by the precise utility necessities. Schedule 40 represents a great compromise between power and price. Nevertheless, for higher-pressure functions, increased schedules like Schedule 80 and even increased is likely to be crucial. Conversely, for low-pressure functions, decrease schedules like Schedule 10 is likely to be ample, providing price financial savings.

Significance of Correct Information and Compliance:

Utilizing the right thickness knowledge from a dependable supply is paramount. Incorrect knowledge can result in design errors, leading to pipe failure, leaks, and probably catastrophic penalties. At all times check with respected sources for Schedule 40 thickness knowledge, guaranteeing compliance with related business requirements and rules. Seek the advice of with skilled engineers and designers to make sure the suitable pipe schedule is chosen for the supposed utility.

Past the Chart: Additional Issues

The Schedule 40 thickness chart supplies important dimensional knowledge, nevertheless it’s not the one issue to think about when deciding on MS pipes. Different crucial facets embody:

- Materials Grade: The particular grade of gentle metal used impacts the pipe’s power and corrosion resistance.

- Floor End: The floor end can have an effect on the pipe’s corrosion resistance and its suitability for particular functions.

- Corrosion Safety: Relying on the applying, extra corrosion safety measures is likely to be crucial, reminiscent of coatings or linings.

- Welding Necessities: If welding is required, the chosen pipe schedule and materials grade should be appropriate with the welding course of.

Conclusion:

The MS pipe Schedule 40 thickness chart is a elementary instrument for engineers, designers, and contractors concerned in piping methods. Understanding find out how to interpret this chart and contemplating the components influencing pipe choice is essential for guaranteeing the security, reliability, and longevity of any piping system. At all times prioritize accuracy, compliance with related requirements, {and professional} session to make sure the proper pipe is chosen for the precise utility, maximizing security and minimizing potential dangers. Commonly updating data of related requirements and greatest practices is crucial to stay knowledgeable about developments in supplies and design concerns for MS pipe choice.

Closure

Thus, we hope this text has offered useful insights into Decoding the MS Pipe Schedule 40 Thickness Chart: A Complete Information. We hope you discover this text informative and helpful. See you in our subsequent article!