Decoding the Filament Jungle: A Complete Information to 3D Printer Filament Varieties

Associated Articles: Decoding the Filament Jungle: A Complete Information to 3D Printer Filament Varieties

Introduction

With nice pleasure, we’ll discover the intriguing matter associated to Decoding the Filament Jungle: A Complete Information to 3D Printer Filament Varieties. Let’s weave fascinating data and supply recent views to the readers.

Desk of Content material

Decoding the Filament Jungle: A Complete Information to 3D Printer Filament Varieties

The world of 3D printing is huge and thrilling, however navigating the myriad of filament choices can really feel overwhelming, even for knowledgeable customers. Understanding the properties and functions of various filament sorts is essential for attaining profitable prints and realizing your artistic visions. This complete information serves as an in depth reference chart and clarification of frequent 3D printer filaments, breaking down their traits, benefits, and limitations that will help you select the precise materials to your undertaking.

This text goes past a easy chart, offering in-depth evaluation of every filament sort, together with their thermal properties, mechanical strengths, print settings, and greatest use instances. We’ll discover each frequent and specialised filaments, empowering you to make knowledgeable selections and unlock the total potential of your 3D printer.

I. The Filament Household Tree: A Categorization Strategy

Earlier than diving into specifics, it’s useful to categorize filaments primarily based on their base materials:

- Thermoplastics: That is the commonest class, encompassing supplies that soften when heated and solidify upon cooling. Nearly all of filaments fall beneath this umbrella.

- Thermosets: These supplies bear an irreversible chemical change when cured, leading to a completely hardened construction. They’re much less frequent in desktop 3D printing.

- Composites: These filaments mix a base thermoplastic with components like fibers, steel powders, or different supplies to reinforce particular properties.

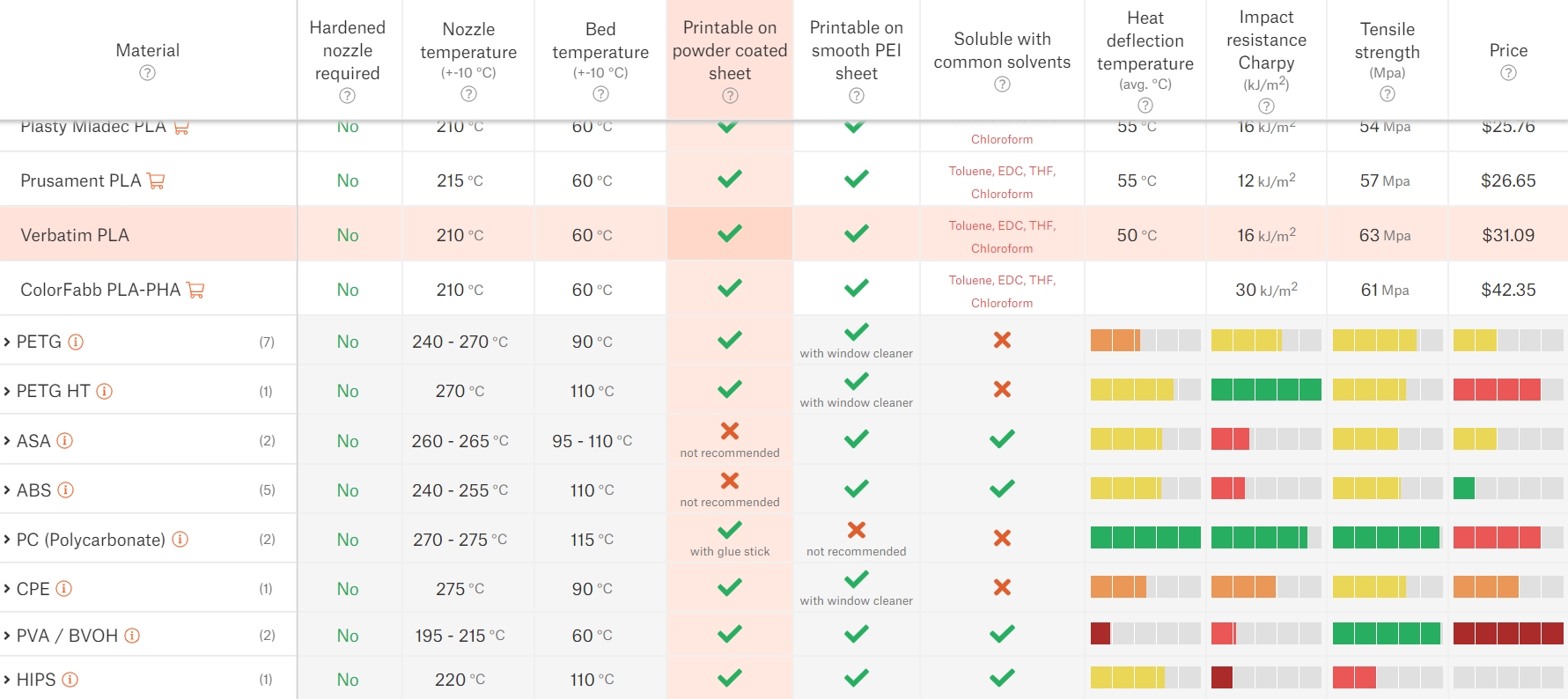

II. Detailed Filament Kind Chart and Explanations:

The next chart summarizes key traits, adopted by detailed explanations for every filament sort:

| Filament Kind | Base Materials | Power | Flexibility | Warmth Resistance | Print Temperature (°C) | Functions | Benefits | Disadvantages |

|---|---|---|---|---|---|---|---|---|

| PLA (Polylactic Acid) | Corn Starch/Sugarcane | Medium | Low | Low | 180-220 | Prototyping, Fashions, Toys, On a regular basis Objects | Simple to print, Biodegradable, Comparatively low-cost | Brittle, Low warmth resistance, Susceptible to warping |

| ABS (Acrylonitrile Butadiene Styrene) | Petroleum | Excessive | Low | Medium | 210-250 | Sturdy components, housings, useful prototypes | Sturdy, Sturdy, Good affect resistance | Warping inclined, Requires enclosed printer, Poisonous fumes |

| PETG (Polyethylene Terephthalate Glycol) | Petroleum | Excessive | Medium | Medium | 220-260 | Bottles, containers, useful components | Sturdy, Sturdy, Good layer adhesion, Moisture resistant | Barely harder to print than PLA |

| ASA (Acrylonitrile Styrene Acrylate) | Petroleum | Excessive | Low | Excessive | 230-260 | Outside functions, automotive components | UV resistant, Excessive temperature tolerance, Sturdy | Costlier than PLA and ABS, requires heated mattress |

| TPU (Thermoplastic Polyurethane) | Petroleum | Medium | Excessive | Low | 210-240 | Versatile components, seals, grips, filaments | Versatile, Sturdy, Abrasion resistant | Might be troublesome to print, vulnerable to stringing |

| Nylon (Polyamide) | Petroleum | Excessive | Medium | Medium | 230-260 | Sturdy components, useful prototypes, engineering components | Sturdy, Sturdy, affect resistant, chemical resistant | Requires exact temperature management, vulnerable to warping |

| PC (Polycarbonate) | Petroleum | Very Excessive | Low | Excessive | 260-300 | Excessive-strength components, industrial functions | Extraordinarily robust, excessive warmth resistance, affect resistant | Tough to print, requires excessive temperatures, costly |

| PET (Polyethylene Terephthalate) | Petroleum | Excessive | Low | Medium | 220-260 | Bottles, containers, robust components | Sturdy, Sturdy, Chemical resistant | Might be troublesome to print, vulnerable to warping |

| PP (Polypropylene) | Petroleum | Medium | Excessive | Medium | 160-220 | Versatile components, containers | Versatile, Chemical resistant, meals protected | Might be troublesome to print, requires excessive temperatures |

| ABS-PC Mix | Petroleum | Very Excessive | Low | Excessive | 240-280 | Excessive-strength, heat-resistant components | Combines the energy of PC with the printability of ABS | Costlier, requires exact temperature management |

III. Detailed Filament Kind Evaluation:

A. PLA (Polylactic Acid): The Newbie’s Selection

PLA is the most well-liked filament for inexperienced persons as a consequence of its ease of printing. Derived from renewable assets like corn starch or sugarcane, it is biodegradable and comparatively cheap. Its low printing temperature (180-220°C) makes it appropriate for many printers with out a heated mattress. Nevertheless, its low warmth resistance and brittleness restrict its functions to non-structural components and prototypes. Warping might be a difficulty, particularly with bigger prints.

B. ABS (Acrylonitrile Butadiene Styrene): The Workhorse

ABS is thought for its energy, sturdiness, and affect resistance. It is typically used for useful prototypes and components requiring larger energy. Nevertheless, ABS printing requires a heated mattress and an enclosed printer to forestall warping. It additionally releases poisonous fumes throughout printing, necessitating good air flow.

C. PETG (Polyethylene Terephthalate Glycol): The Versatile All-Rounder

PETG combines the energy of ABS with improved layer adhesion and moisture resistance. It is simpler to print than ABS, much less vulnerable to warping, and presents higher floor end. Its versatility makes it appropriate for a variety of functions, from bottles and containers to useful components.

D. ASA (Acrylonitrile Styrene Acrylate): The Outside Champion

ASA boasts distinctive UV resistance, making it very best for out of doors functions. It presents comparable energy and sturdiness to ABS however with considerably higher warmth and UV resistance. Its larger printing temperature requires a heated mattress and infrequently an enclosed printer.

E. TPU (Thermoplastic Polyurethane): The Versatile Buddy

TPU is a versatile filament identified for its elasticity and abrasion resistance. It is used for components requiring flexibility, similar to seals, grips, and versatile housings. Nevertheless, its tendency to string and persist with the nozzle could make it difficult to print.

F. Nylon (Polyamide): The Excessive-Efficiency Materials

Nylon presents excessive energy, toughness, and chemical resistance. It is typically used for useful prototypes and engineering components requiring excessive sturdiness. Nevertheless, it requires exact temperature management and might be vulnerable to warping. Moisture absorption may have an effect on its printing properties.

G. PC (Polycarbonate): The Final Power Materials

PC is a high-performance materials with distinctive energy, warmth resistance, and affect resistance. It is very best for demanding functions however requires excessive printing temperatures (260-300°C) and specialised gear. Its excessive viscosity could make it difficult to print.

H. PET (Polyethylene Terephthalate): The Sturdy and Chemical Resistant Possibility

Much like PETG, PET presents excessive energy and chemical resistance. Nevertheless, it is usually harder to print than PETG and might be vulnerable to warping.

I. PP (Polypropylene): The Versatile and Meals-Protected Selection

PP is a versatile materials identified for its chemical resistance and meals security. It is appropriate for functions requiring flexibility and chemical inertness. Nevertheless, it requires excessive printing temperatures and might be difficult to print.

IV. Past the Fundamentals: Specialised Filaments

The world of 3D printing filaments extends far past the frequent supplies mentioned above. Specialised filaments supply distinctive properties and capabilities, catering to various wants:

- Wooden Filaments: Mix plastic with wooden fibers, providing a pure, textured end.

- Carbon Fiber Filaments: Improve energy and stiffness, very best for high-performance components.

- Steel-Crammed Filaments: Incorporate steel powders for improved energy, conductivity, and aesthetic attraction (e.g., bronzeFill, copperFill).

- Glow-in-the-Darkish Filaments: Comprise phosphorescent pigments for illuminating results.

- Magnetic Filaments: Embedded with magnetic particles, permitting for magnetic properties in printed objects.

- Conductive Filaments: Allow electrical conductivity for circuits and sensors.

- Versatile Filaments (past TPU): Varied versatile supplies exist with completely different ranges of flexibility and properties.

V. Selecting the Proper Filament: A Choice-Making Framework

Choosing the suitable filament requires cautious consideration of your undertaking’s necessities:

- Mechanical Properties: Take into account the mandatory energy, flexibility, and affect resistance.

- Thermal Properties: Assess the required warmth resistance and working temperature.

- Chemical Resistance: Decide the extent of publicity to chemical substances or solvents.

- Aesthetic Concerns: Select a filament that meets your required shade, texture, and end.

- Printer Compatibility: Guarantee your printer’s capabilities align with the filament’s printing temperature and materials properties.

- Finances: Filament costs fluctuate considerably.

VI. Conclusion:

The varied vary of 3D printer filaments presents countless potentialities for creativity and innovation. By understanding the distinctive properties and functions of every filament sort, you’ll be able to unlock the total potential of your 3D printer and convey your designs to life with precision and effectivity. This complete information serves as a worthwhile useful resource, empowering you to make knowledgeable selections and navigate the thrilling world of 3D printing supplies with confidence. Bear in mind to at all times seek the advice of the producer’s specs for optimum printing outcomes and security precautions.

Closure

Thus, we hope this text has supplied worthwhile insights into Decoding the Filament Jungle: A Complete Information to 3D Printer Filament Varieties. We respect your consideration to our article. See you in our subsequent article!