Decoding the 410A Line Set Sizing Chart: A Complete Information for HVAC Professionals

Associated Articles: Decoding the 410A Line Set Sizing Chart: A Complete Information for HVAC Professionals

Introduction

With nice pleasure, we are going to discover the intriguing subject associated to Decoding the 410A Line Set Sizing Chart: A Complete Information for HVAC Professionals. Let’s weave attention-grabbing data and provide contemporary views to the readers.

Desk of Content material

Decoding the 410A Line Set Sizing Chart: A Complete Information for HVAC Professionals

The correct sizing of refrigerant line units is essential for the environment friendly and dependable operation of any air-con or refrigeration system. Utilizing an improperly sized line set can result in lowered cooling capability, elevated power consumption, compressor overheating, and in the end, untimely tools failure. That is notably true with R-410A methods, which function at greater pressures than their R-22 predecessors. This text gives a complete information to understanding and using 410A line set sizing charts, protecting key elements, calculation strategies, and troubleshooting widespread points.

Understanding R-410A and its Influence on Line Set Sizing

R-410A, a hydrofluoroolefin (HFO) refrigerant, is broadly utilized in fashionable HVAC methods attributable to its greater effectivity and environmental friendliness in comparison with R-22. Nevertheless, its greater working pressures necessitate cautious consideration when choosing line set parts. The elevated strain necessitates thicker and extra strong tubing to resist the stress, influencing the choice course of considerably. Improper sizing can result in:

- Elevated refrigerant strain drop: This reduces the system’s cooling capability and effectivity.

- Liquid slugging: Inadequate liquid line measurement may cause liquid refrigerant to slug via the system, damaging the compressor.

- Compressor overheating: Outsized suction traces may cause extreme refrigerant stream, resulting in compressor overheating and potential failure.

- Lowered effectivity: Each undersized and outsized line units contribute to lowered system effectivity and elevated power prices.

Key Components Affecting 410A Line Set Sizing

A number of elements have to be thought-about when choosing the suitable 410A line set:

- Refrigerant Kind: R-410A’s greater working pressures dictate the necessity for heavier-walled tubing than methods utilizing R-22.

- System Capability (BTU/hr): The cooling capability of the system instantly influences the refrigerant stream price and, consequently, the required line set measurement. Bigger methods necessitate bigger line units.

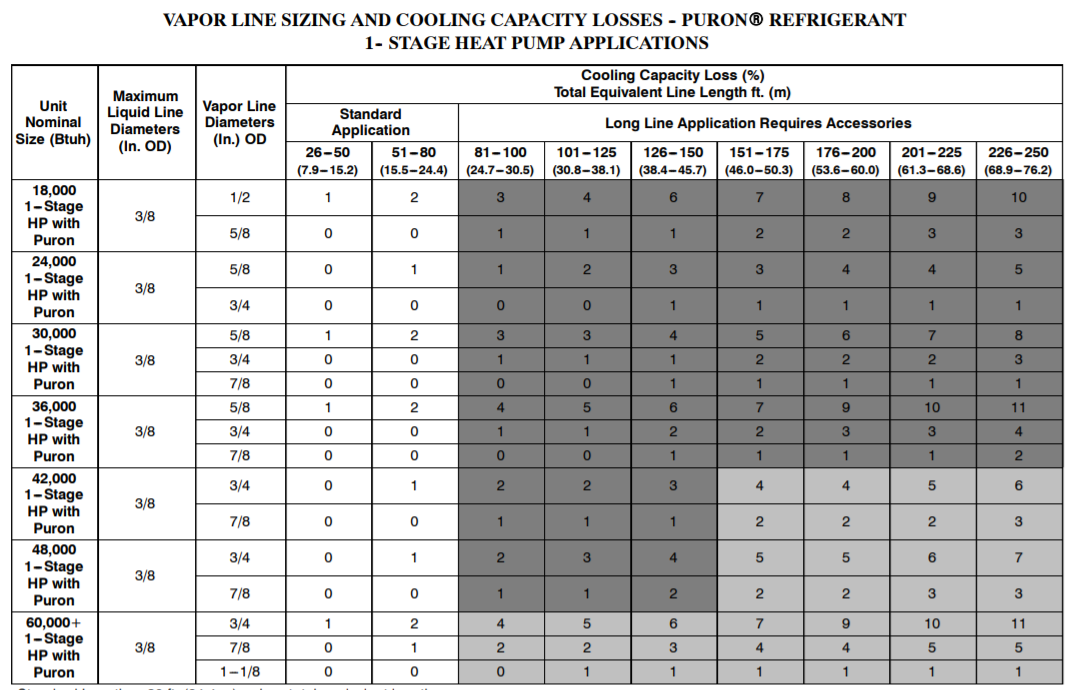

- Tools Producer’s Specs: At all times seek advice from the producer’s specs for the precise air-con or refrigeration unit. They supply the really helpful line set sizes based mostly on their tools’s design parameters.

- Line Set Size: Longer line units expertise better strain drop attributable to friction. Longer runs require bigger diameter traces to compensate for this loss.

- Elevation Change: Vital elevation adjustments between the indoor and outside models additionally have an effect on strain drop. Upward elevation adjustments improve strain, whereas downward adjustments lower strain.

- Variety of Bends and Fittings: Every bend and becoming within the line set introduces further resistance to refrigerant stream, requiring doubtlessly bigger diameter traces.

- Ambient Temperature: Excessive ambient temperatures can have an effect on refrigerant strain and stream, doubtlessly necessitating changes to line set sizing.

Deciphering a 410A Line Set Sizing Chart

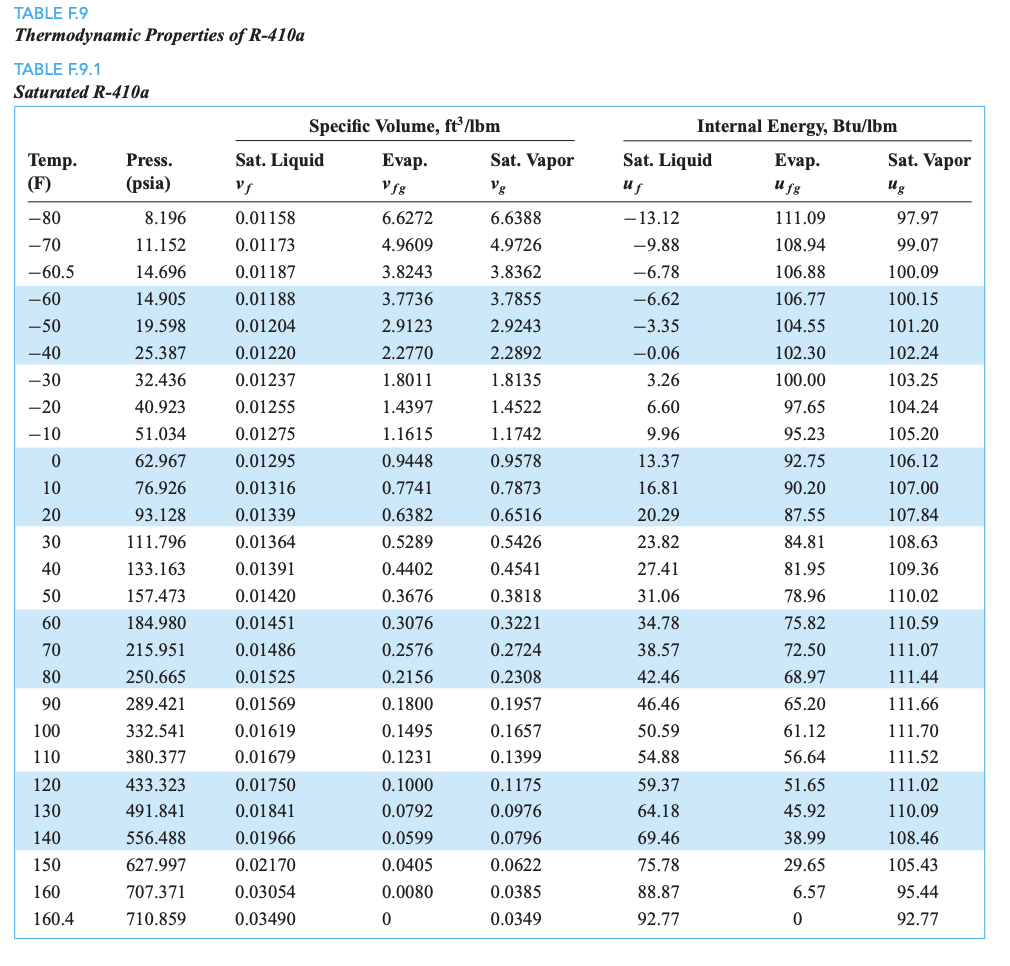

A typical 410A line set sizing chart is often introduced in a tabular format. It usually consists of the next data:

- System Capability (BTU/hr or kW): This represents the cooling capability of the HVAC system.

- Liquid Line Diameter (OD): This specifies the surface diameter of the liquid line tubing.

- Suction Line Diameter (OD): This specifies the surface diameter of the suction line tubing.

- Most Line Set Size: This means the utmost allowable size for the precise line set measurement. Exceeding this size can result in inadequate cooling capability.

- Elevation Change (if relevant): Some charts embrace pointers for adjusting line set measurement based mostly on elevation adjustments.

Calculation Strategies (Simplified Method):

Whereas detailed calculations usually require specialised software program, a simplified strategy can be utilized for preliminary estimations:

- Decide the system’s cooling capability (BTU/hr).

- Seek advice from a producer’s line set sizing chart or a good on-line useful resource. Discover the row akin to the system’s capability.

- Determine the really helpful liquid and suction line diameters.

- Contemplate the road set size and elevation change. If the road set size exceeds the utmost size specified within the chart, improve the road measurement accordingly. Equally, modify the road measurement for vital elevation adjustments.

- Add a security margin: It is at all times advisable to barely oversize the road set to account for surprising strain drops or future system expansions.

Troubleshooting Widespread Points:

- Inadequate Cooling Capability: This might point out an undersized line set, particularly the liquid line. Verify for restrictions, leaks, or extreme line size.

- Compressor Overheating: This implies an outsized suction line, permitting an excessive amount of refrigerant stream. Confirm the road set measurement and verify for any obstructions.

- Liquid Slugging: This means an undersized liquid line. Verify for correct slope and make sure the liquid line is sufficiently sized.

- Excessive Refrigerant Stress: This could possibly be attributable to an undersized liquid line or restrictions within the system. Verify for blockages and confirm the road set measurement.

- Low Refrigerant Stress: This may point out an outsized suction line or leaks within the system. Verify for leaks and confirm the road set measurement.

Superior Concerns:

- Stress Drop Calculations: For extra correct sizing, notably in advanced installations, software program or specialised engineering calculations must be used to find out the strain drop throughout the road set. These calculations bear in mind the precise refrigerant properties, line size, elevation adjustments, variety of bends, and the inner diameter of the tubing.

- Materials Choice: Line units are usually made from copper tubing. The wall thickness is essential for withstanding the excessive pressures of R-410A. Make sure the tubing meets the suitable requirements.

- Insulation: Correct insulation of the road set minimizes warmth switch, enhancing effectivity and lowering refrigerant strain fluctuations. The insulation thickness must be chosen based mostly on the ambient temperature and line set size.

- Correct Set up Strategies: Appropriate set up practices are important to make sure the correct functioning of the road set. This consists of correct flaring, brazing, and leak testing.

Conclusion:

Deciding on the suitable 410A line set is important for optimum HVAC system efficiency. Whereas manufacturer-specific charts present a place to begin, understanding the important thing elements influencing line set sizing and using acceptable calculation strategies permits for extra correct sizing and avoids potential issues. By rigorously contemplating the system capability, line size, elevation adjustments, and different related elements, HVAC professionals can make sure the environment friendly and dependable operation of R-410A methods for years to return. Do not forget that consulting with skilled professionals and using specialised software program for advanced installations is at all times really helpful for finest outcomes. Ignoring correct line set sizing can result in pricey repairs and vital effectivity losses, highlighting the significance of meticulous planning and execution.

Closure

Thus, we hope this text has supplied priceless insights into Decoding the 410A Line Set Sizing Chart: A Complete Information for HVAC Professionals. We recognize your consideration to our article. See you in our subsequent article!