Decoding ISO 2768-m: A Complete Information to Tolerance Grades for Linear and Angular Dimensions

Associated Articles: Decoding ISO 2768-m: A Complete Information to Tolerance Grades for Linear and Angular Dimensions

Introduction

With nice pleasure, we are going to discover the intriguing matter associated to Decoding ISO 2768-m: A Complete Information to Tolerance Grades for Linear and Angular Dimensions. Let’s weave fascinating data and supply contemporary views to the readers.

Desk of Content material

Decoding ISO 2768-m: A Complete Information to Tolerance Grades for Linear and Angular Dimensions

ISO 2768-m is a extensively used worldwide customary that defines basic tolerances for linear and angular dimensions in technical drawings. In contrast to requirements that specify tolerances for particular components or industries, ISO 2768-m gives a system of basic tolerances, simplifying the drafting course of and selling consistency throughout numerous engineering purposes. This text gives a complete overview of ISO 2768-m, explaining its construction, software, and sensible implications for engineers and designers.

Understanding the Basis: Common Tolerances for Linear and Angular Dimensions

Earlier than delving into the specifics of ISO 2768-m, it is essential to grasp the idea of basic tolerances. These are default tolerances utilized to dimensions until explicitly overridden by particular person tolerance specs on the drawing. This simplifies drawings, lowering muddle and bettering readability. Nevertheless, it is equally necessary to grasp that the usage of basic tolerances implies an acceptance of a sure degree of dimensional variation. The selection of the suitable tolerance grade is crucial for making certain the performance and interchangeability of components.

ISO 2768-m gives a number of tolerance grades, denoted by "m," "c," "f," and "g" (with "m" being the main target of this text). Every grade represents a special degree of precision. "m" represents a medium tolerance grade, appropriate for a variety of purposes the place reasonable precision is required. The opposite grades ("c," "f," and "g") present tighter (c, f) or looser (g) tolerances, respectively.

The Construction of ISO 2768-m Tolerance Chart

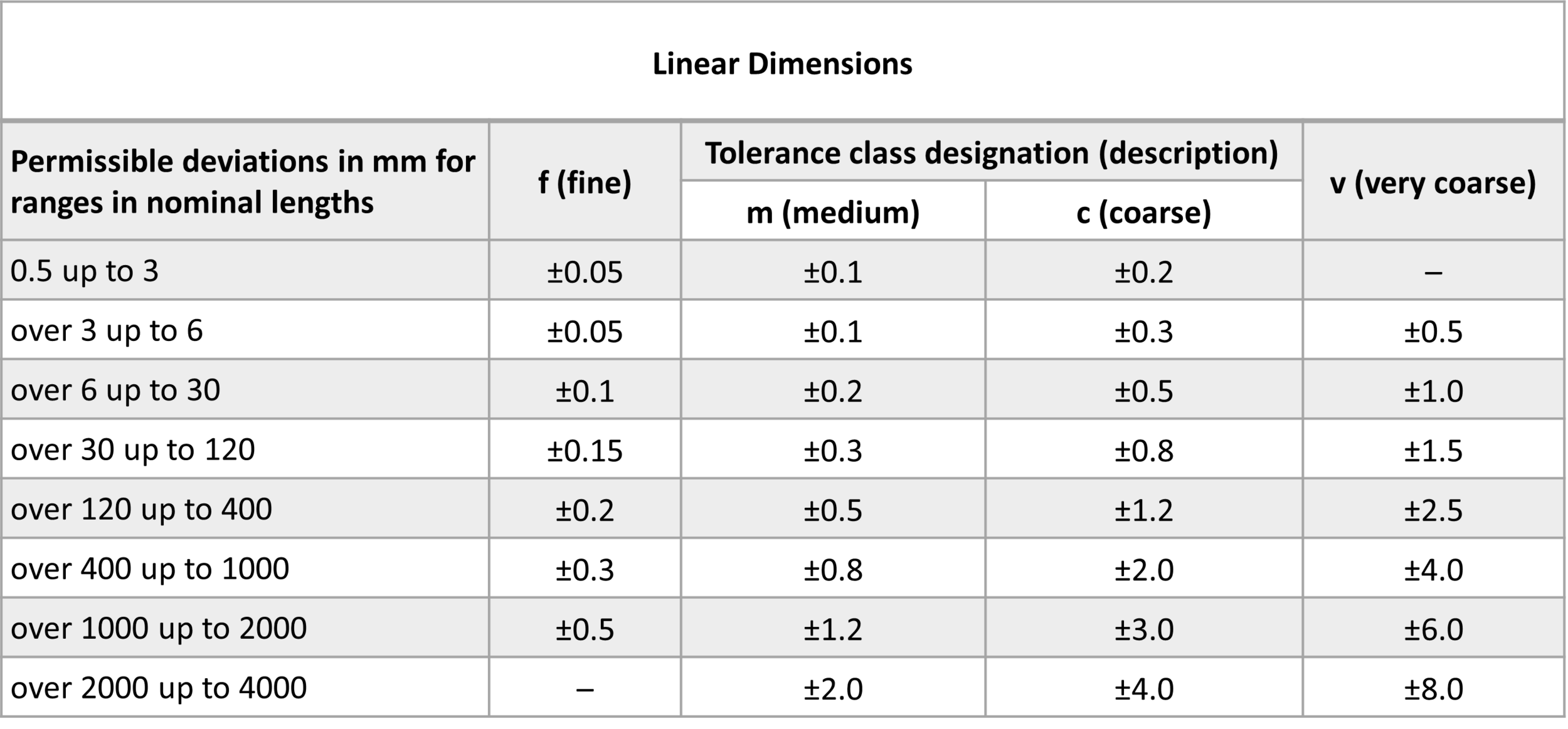

The ISO 2768-m customary presents its tolerance grades within the type of a chart or desk. This chart sometimes organizes tolerances primarily based on the nominal measurement of the dimension. The nominal measurement is the essential dimension specified on the drawing, earlier than the tolerance is utilized. The chart then gives the corresponding tolerance worth for every nominal measurement vary.

The tolerance values are normally expressed as a plus/minus (±) worth, indicating the permissible deviation from the nominal measurement. For instance, a tolerance of ±0.1 mm implies that the precise dimension can differ by as much as 0.1 mm above or beneath the nominal measurement. The tolerance chart is structured to make sure that the tolerance will increase because the nominal measurement will increase. This displays the sensible actuality that bigger components are usually extra tolerant of better dimensional variations than smaller components.

Decoding the ISO 2768-m Chart: A Sensible Instance

Let’s contemplate a hypothetical instance. Suppose a drawing specifies a shaft with a nominal diameter of 25 mm. Referring to the ISO 2768-m chart, we discover the tolerance for a 25 mm dimension below the "m" grade. Let’s assume the chart signifies a tolerance of ±0.15 mm. Because of this the suitable vary for the shaft diameter is 24.85 mm to 25.15 mm. Any shaft with a diameter falling inside this vary can be thought-about acceptable in line with the ISO 2768-m "m" grade.

The Significance of Tolerance Zones and Limits

The ISO 2768-m tolerance defines a tolerance zone, which is the vary of acceptable dimensions. The higher and decrease limits of this zone are decided by including and subtracting the tolerance worth from the nominal measurement, respectively. Understanding these limits is essential for manufacturing and inspection processes. Elements falling outdoors the outlined tolerance zone are thought-about non-conforming and will require rework or rejection.

Benefits of Utilizing ISO 2768-m

The utilization of ISO 2768-m gives a number of important benefits:

- Simplified Drawings: By utilizing basic tolerances, the variety of dimensions and annotations on drawings is lowered, bettering readability and readability.

- Improved Consistency: The usual ensures a constant strategy to tolerancing throughout numerous initiatives and organizations, minimizing misunderstandings and errors.

- Diminished Design Time: The pre-defined tolerance grades streamline the design course of, saving invaluable time and assets.

- Enhanced Interchangeability: Using standardized tolerances promotes the interchangeability of components, facilitating meeting and lowering manufacturing prices.

- Facilitated Communication: A typical understanding of tolerances fosters higher communication between designers, producers, and inspectors.

Limitations and Concerns when utilizing ISO 2768-m

Whereas ISO 2768-m gives important advantages, it is essential to acknowledge its limitations:

- Common Nature: The tolerances are basic and will not all the time be appropriate for all purposes. Vital dimensions or these requiring greater precision would possibly necessitate the specification of particular person tolerances.

- Potential for Over- or Underneath-Specification: The collection of an inappropriate tolerance grade can result in both overly tight tolerances, rising manufacturing prices, or overly unfastened tolerances, compromising performance.

- Lack of Particular Materials Concerns: ISO 2768-m would not account for the particular materials properties that may affect dimensional stability and tolerances.

- Requirement for Cautious Choice: Selecting the right tolerance grade requires cautious consideration of the applying, performance necessities, and manufacturing capabilities.

Past "m": Different Tolerance Grades in ISO 2768

Whereas this text focuses totally on the "m" grade, it is necessary to briefly point out the opposite grades outlined in ISO 2768:

- "c" Grade: Gives tighter tolerances than "m," appropriate for purposes requiring greater precision.

- "f" Grade: Gives even tighter tolerances than "c," excellent for purposes demanding very excessive precision.

- "g" Grade: Gives looser tolerances than "m," appropriate for purposes the place much less precision is required.

The selection of the suitable tolerance grade depends upon the particular software and the required degree of precision. An intensive understanding of the applying’s purposeful necessities and manufacturing capabilities is important for choosing essentially the most appropriate tolerance grade.

Conclusion: A Highly effective Device for Engineering Precision

ISO 2768-m gives a standardized and environment friendly system for specifying tolerances in technical drawings. Its use simplifies the design course of, promotes consistency, and enhances communication amongst stakeholders. Nevertheless, its efficient software requires a radical understanding of its construction, limitations, and the implications of selecting a particular tolerance grade. By rigorously contemplating the applying’s necessities and using the suitable tolerance grade, engineers and designers can leverage the facility of ISO 2768-m to make sure the precision and reliability of their designs. The "m" grade, with its medium tolerance degree, stays a flexible and extensively used possibility for a big spectrum of engineering purposes, providing a steadiness between precision and manufacturing feasibility. All the time seek the advice of the complete ISO 2768 customary for essentially the most correct and up-to-date data and to pick essentially the most applicable grade for a given software.

Closure

Thus, we hope this text has offered invaluable insights into Decoding ISO 2768-m: A Complete Information to Tolerance Grades for Linear and Angular Dimensions. We respect your consideration to our article. See you in our subsequent article!